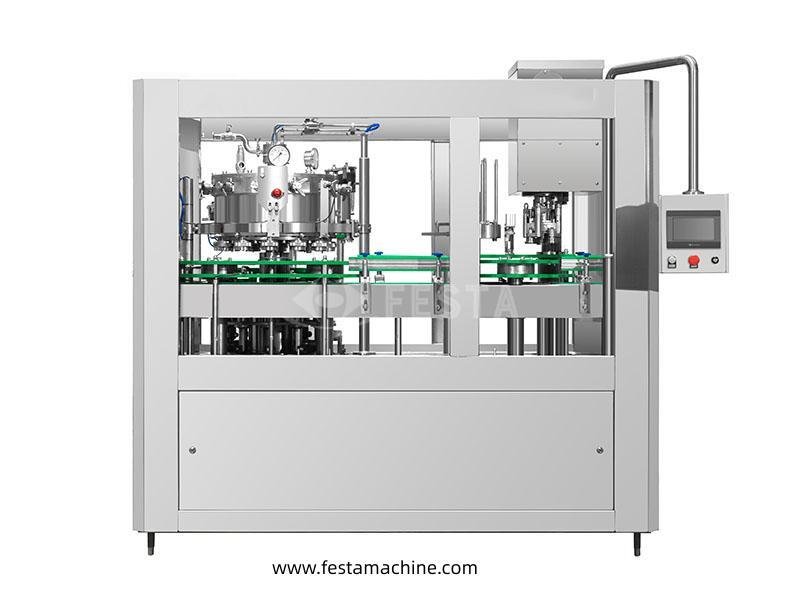

YPGF12-1 Beer Can Filling and Seaming 2 in 1 Machine

Production Capacity: 1000-2000 cans per hour

Machine Power: 2.2kw

Filling Method: Beer isobaric filling

Suitable: Beer can, PET can

Benefit of FESTA YPGF12-1 Beer Canning Machine

This machine cleverly combines 12 heads beer can filling machine and automatic single head can sealing machine into one machine, which is suitable for the production of beer, carbonated drinks, soda water, sparkling water and other canned beverages. It has fast filling speed, precise liquid level control, reliable can lid sealing and low material loss. Compared with the traditional split type machine, this machine can save labor cost and occupy a much smaller area, which is the preferred can filling equipment for small breweries.

Description

After entering the beer can filling machine, the empty cans on the conveyor belt are separated by the can dividing unit, and then enter the lower part of the filling valve by the star wheel. When the empty can rotates with the filling valve, it is lifted by the lifting cylinder so that the mouth of the can forms a seal with the valve mouth. The filling machine fills the can with carbon dioxide gas first, and when the pressure inside the can is the same as the pressure of the liquid cylinder, the beer filling valve is opened for beer filling. After filling to the set liquid level, the filling valve closes, while the exhaust valve opens to discharge the excess CO2, thus completing the beer filling process. The filled cans are passed from the star wheel to the easy-open can sealing machine.

All pipes and main parts in contact with liquid are made of food-grade stainless steel 316L, which is safe, reliable and easy to clean.

1) Anti-corrosion and lubrication-free bearings with European technology are used to effectively avoid potential pollution of beer by lubricants.

2)The beer filling valve adopts mechanical structure, the technology originates from Italy, stable and reliable, fast filling speed, no sanitary dead angle, the whole valve is made of 316 stainless steel, which meets food grade standard.

3)The filling machine comes with washable pipeline, which can be connected to automatic CIP equipment for thorough cleaning of the filling valve, liquid cylinder and liquid circuit.

4)The main machine is equipped with automatic temperature control system to ensure the constant filling temperature.

6)The beer supply adopts automatic pneumatic valve magnetic level switch to automatically control the amount of beer in the filling liquid cylinder.

7) The main power of the filling machine comes from the motor, which is transmitted to each rotating part through gears, with simple structure, stable and reliable

Data Sheet

Can Filling Heads | 12 |

Can Seamer Head | 1 |

Production Capacity | 1000-2000CPH(500ml) |

Suitable can size | Height: 90~180mm; Diameter: Φ 50~ Φ 85mm |

Filling Pressure | 0.3-0.5Mpa |

Compressed Air Consumption | 0.2m³/Min 0.5-0.6Mpa |

CO2 Consumption | 260g/100L |

Main Motor Power | 2.2KW |

Dimension | 2100×1300×2050 mm |

Weight | 1950KG |