Your Trustworthy Water Bottling Machine Manufacturer in China

- High stability of our equipment

- Customize your machine

- Compatible with different bottle shapes

- The machine is made of stainless steel

Your Premier Water Bottling Equipment Supplier

The main material of FESTA water bottling machine is stainless steel, we produced and manufactured our machines by European technology, with stable machine performance and timely after-sales service. As a professional water bottling machinery manufacturer, we have rich engineering experience and can customize machines for different liquids and bottle types. Our machines have passed ISO, CE, SGS, SONCAP and other certifications. Different customers can find satisfactory solutions in FESTA. Your just tell us your bottle water idea, and we will help you make it happen.

It is FESTA’s smallest washing filling capping 3 in 1 monoblock. The whole machine adopts one-piece fuselage with high hardware configuration and can be bottled up to 3000 bottles per hour.

- Production Capacity: 2,000-3,000 bottles per hour

- Machine Power: 2.2kw

- Dimension: 2200X1500X2280mm

When you need a bottling machine with moderate production capacity, then our CXGF12-12-6 water bottling monoblock is your best choice, which can steadily produce 4000-5000 bottles of water per hour.

- Production Capacity: 4,000-5,000 bottles per hour

- Machine Power: 2.5kw

- Dimension: 2500X1700X2350mm

This machine is our best-selling 3 in 1 water bottling machine, its production capacity is 6000-8000 bottles per hour (500ml), with automatic empty bottle cleaning, automatic filling, automatic capping and other functions.

- Production Capacity: 6,000-8,000 bottles per hour

- Machine Power: 3kw

- Dimension: 2800X2130X2370mm

This is a mainstream fully automatic water bottling machine in the market with a production capacity of 10000-12000BPH. Use Mitsubishi touch screen, Mitsubishi PLC and Mitsubishi frequency converter control, compatible with multiple bottle capacity.

- Production Capacity: 10,000-12,000 bottles per hour

- Machine Power: 4kw

- Dimension: 3100X2340X2350mm

This machine is our high-speed automatic bottling machine with a production capacity of up to 300 bottles per minute. It is widely favored by large enterprises. The whole machine adopts a large number of automatic control original parts to ensure the stability of high-speed operation.

- Production Capacity: 16,000-18,000 bottles per hour

- Machine Power: 5.5kw

- Dimension: 4110X2740X2700mm

5 liter & One Gallon Water Bottling Machine

It used it to bottle water into large PET container. The maximum production capacity is no more than 1000 bottles per hour. Compatible with 3 liter, 4 liter, 1 gallon, 5 liter, 10 to 15 liter PET bottles.

- Production Capacity: 600-1000 bottles per hour

- Machine Power: 2.5kw

- Dimension: 3200X2200X2700mm

This is our medium capacity large PET bottle 3 in 1 water filling equipment. It can produce 1500 bottles per hour, which integrates bottle washing, filling and capping functions. Complete the bottling procedure automatically.

- Production Capacity: 1200-1500 bottles per hour

- Machine Power: 4kw

- Dimension: 3560X2500X2700mm

The machine adopts high-speed, high-precision electromagnetic Flowmeter rotary filling system, with a total of 16 independent filling valves. The use of non-contact filling technology is more hygienic, and it is easier to switch the bottle type. The filling capacity can be set on the touch screen.

- Production Capacity: 1500-2000 bottles per hour

- Machine Power: 2.2kw

- Dimension: 3600X2960X2700mm

5 Gallon Barrel Water Bottling Machine

After decades of industry development, 5-gallon bottled water is still popular with consumers. FESTA 5 gallon water bottling machine has reached the industry-leading level through update iteration and technology upgrade. The flushing of the empty bucket is more thorough, and the filling level is more accurate.

- Production Capacity: 150-900 bottles per hour(5 Gallon)

- Machine Technology: Linear Type Washer Filling Capper

- Suitable: 5 Gallon PC bottle, 5 Gallon PET Bottle

When customers need a production capacity of more than 1200 barrels per hour, we recommend that customers choose a rotary 5-gallon water bottling equipment. The 5-gallon water machine with rotary filling system is compact, more efficient and more scientific.

- Production Capacity: 1200-2000BPH(5 Gallon)

- Machine Technology: Rotary Filler Bottling

- Suitable: 5 Gallon Barrel Bottle

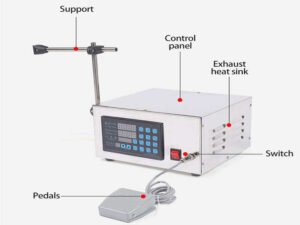

Semi-auto Water Bottling Machine

Small scale semi-auto bottle water machine, suitable for a low cost water bottling plant.

- Production Capacity: 500-1500BPH

- Machine Power: 0.75

- Dimension: 930*770*1630mm

Applicable liquids: all low viscosity liquids. Unsuitable liquids: very thick liquids (sauces, detergents, etc.) or liquids containing small particles.

- Production Capacity: 300-800BPH

- Machine Power: 0.1kw

- Dimension: 360*255*170mm

Related Equipment of Complete Water Bottling Line

One Stop Customized Water Bottling Solution

FESTA can design different intercept bottling equipment according to customer’s bottle size. We can also use of different filling methods according to customer demand, for example mechanical filling valve, flow meter filling valve, negative pressure filling valve, gravity filling and so on.

High Stability Machine for Your Bottling Plant

In order to improve the quality of the machine, we use CNC processing to ensure the accuracy. Always follow standard assembly procedures during machine manufacturing. We use the best electrical components to ensure that the machine will not fail to stop in the long production process.

A Wide Range Production Capacity for You Choose

Our minimum capacity bottler is only 200 bottles per hour, and our largest automatic water bottling equipment can reach 36,000 bottles per hour (based on 500ml bottles). Whether you make small bottle water or 5 gallon water, you can always find the ideal machine for your factory at FESTA.

Quality Manufacturing Process for Your Water Bottling Machine

FESTA water bottling equipment takes full account of the reasonable layout of various parts in the design, which makes it convenient for engineers to wiring, install motors, cylinders and welding frames.

The engineer can quickly disassemble and install the filling valves, capping heads, and adjust the height of the machine. When producing different volume bottle water, fast moulds can be used to reduce the replacement time and improve production efficiency.

We always improve the design and stability of the machine from the customer’s point of view, in order to bring you the best bottling equipment.

Come to Meet Us

We based in China, we have a big factory to produce quality water bottling machines.

Water Bottling Machine: The Ultimate Guide

Water bottling machine, we also call it water bottle filling machine or water bottle filling monoblock. Its main function is to continuously fill a certain amount of water into bottle, which is the most important step in the production process of bottled water. When you produce bottled mineral water, bottled pure water, you need to use water bottling machine.

With the development of bottled water industry, higher requirements are put forward for water bottling machine. FESTA not only provides single bottling machine, but also provides a complete water bottling system solution. From standard configuration to customized configuration, from small production capacity to high production capacity. From bottle washing, filling, capping, cap feeder, cap sorter, cap sterilization machine, OPP hot glue labeling machine to bottle water packing machine. We provide one-stop products and service.

Sorted by liquid

- Mineral water bottling machine

- Purified water bottling equipment

- Drinking water bottle filler

- Still water filling bottle machine

- Coconut water bottler

- Carbonated water bottling machine

Sorted by automation

- Automatic water bottling machine

- Semi-auto water bottling equipment

- Rotary water bottle filling capping monoblock

- Linear water bottle filler

Sorted by container

- PET water bottling machine

- Glass bottling machine

- 5 Gallon water bottling machine

In order to improve the quality of the machine and the stability of operation, we have adopted the highest standard of raw materials. The frame structure of the whole machine is made of high strength carbon steel. The countertop is covered with stainless steel to avoid corrosion. All parts in contact with water (such as liquid tanks, filling valves, bottle washers, etc.) are made of food grade stainless steel 304. Even if water bottling machine runs for a long time, it is still as good as new.

High-quality and stable components also play an important role in the process of stable service for our bottling machine customers. We are never stingy in choosing the best and most widely used parts brands in the world. The pursuit of quality and brand value has always been our persistence. Our commonly used parts brands are listed in the table. Of course, if you have any special requirements, you can also tell us that we can customize water bottling machine according to your idea.

No. | Name | Brand | |

1 | Main Motor | SEW/ABB | Germany |

2 | Solenoid valve, pneumatic component. | SMC/ AIRTAC | Japan/Taiwan |

3 | Main drive bearing. | NSK/SKF | Japan, Sweden |

4 | Sensor. | Banner | USA |

5 | Sealing ring. | Beili | China |

6 | Liquid level float. | Fanyi | China |

7 | Slewing support. | Haoyang | China |

8 | Self-lubricating bearing. | Igus | USA |

9 | Stainless steel. | Posco | China-Korean joint venture |

10 | Water pump | CNP | China |

Decades ago, the water bottling machine can only complete the function of filling water into the bottle, but with the development of water bottling machine technology, the function is becoming more and more perfect. The current bottling machine or water bottling system is a system with a series of functions integrated together, and can better meet the needs of market development.

Empty bottle feeder.

Depending on the size or material of the bottle, you can choose bottle air conveyor or bottle conveyor belt to connect to water bottle filler machine. In this way, continuous feeding of the bottle can be realized without manual placement, and the production efficiency can be greatly improved. According to the needs of customers, you can choose to connect PET bottle blow molding machine or bottle unscrambler to conveyor directly. It can realize large-scale automatic mass production of mineral water and pure water.

Botting rinsing/washing machine

In order to ensure that empty bottles are clean before filling, modern water bottling equipment usually integrates automatic bottle washing function. The empty bottle is transferred to the rotary bottle washing machine through the star wheel, and the steel clip of the bottle washing machine grips the bottle mouth and flips along the guide rail to turn the bottle mouth down. The high-pressure nozzle on the steel clip rinses the empty bottle thoroughly with clean water. After the flushing is completed, the steel clip is turned along the guide rail, the bottle mouth is fed upward into the transition star wheel, and then transferred to the filling process.

Water bottling filling machine

The water filling machine quantitatively fills the water into the empty bottle through the high speed liquid filling valve, and the filling part is the core of the whole filling system. It is equipped with a stainless steel filling tank for storing water, and filling valves are evenly distributed along the circumference in the lower part of the tank. The commonly used filling valve structures are mechanical type and flowmeter type.

Mechanical water filling valve has the advantages of sophisticated structure, mature technology and low price, so it is the most popular filling valve structure for customers.

The Flowmeter filling valve is equipped with an independent Flowmeter on the front pipeline, so the cost is higher, but it has the advantages of faster filling speed and more convenient filling level adjustment, so it is suitable for high-speed production line.

Bottling capping machine

After completing the water filling process, the empty bottle needs to be capped immediately, otherwise the impurities in the air will pollute the bottled water. Capping machine is usually integrated with bottle washing machine and filling machine, which is called water bottle filling monoblock. The capping machine of FESTA adopts constant torque capping head, the capping torque is adjustable and the height of the capping machine is adjustable, which greatly improves the compatibility of the water bottling machine. The production capacity of a single capping head can reach 2000BPH, it is the leading in the industry. The capping cam curve has been iteratively upgraded, which can effectively protect the bottle cap in the process of capping, almost avoiding the situation that the capping is not in place and crooked cap.

Bottle cap feeder

Bottled water must have a lid, otherwise it cannot be sold on the market. Capping machine’s best friend is cap feeder. It can automatically arrange the disordered cap into a prescribed order, automatically send it into the capping machine, and cooperate with the capping machine to complete the last process of water bottling process. Cap feeder comes with a bucket for storing the cap, and the operator only needs to pour the caps into the bucket when there is a cap shortage alarm, which greatly reduces the difficulty of the operator.

Bottle cap sterilization tunnel

In recent years, with people’s attention to food safety, higher requirements have been put forward for the production process of bottled water. In the past, factories only cleaned empty bottles, but ignored the cleanliness of bottle caps. So FESTA developed cap sterilization tunnel for bottle caps. It is mainly installed in the middle of cap feeder and capping machine. It is a tunnel cleaning and sterilizing equipment with all stainless steel structure. The bottle cap is first washed with a certain concentration of disinfectant, then washed with sterile water, and finally dried with aseptic air. After these three procedures, the bottle cap can completely reach a very high degree of cleanliness. The whole cap sterilization tunnel system with pipes, pump and some liquid tanks.

Many customers enter the bottled water industry for the first time, so they don’t know how to make the right choice in a dazzling array of machines. Based on years of experience in the industry, we give you three useful suggestions.

(1) You need to have a plan for bottle size(volume).

Usually, a water bottling machine has a certain compatibility range, such as 300m to 2L can be filled and produced on the same machine.

If the bottle size is between 5L and 15L, it can also be used on the same machine.

There is also a 5 gallon bottle, which needs a special 5 gallon water filling machine to produce.

(2) Tell us the machine production capacity you need.

We need to know that one machine cannot be compatible with 300ml to 5 gallon bottles of all sizes.

FESTA for 300ml to 2L capacity of PET bottled water, machine capacity can be selected from 2000-36000BPH.

5L to 15L capacity of bottled water production, machine capacity range from 400-2000BPH.

5 gallon water filling machine, our production capacity ranges from 150-1500BPH.

BPH means bottles per hour.

(3) Tell us which bottled water label you choose.

The meaning of labels for bottled water is equivalent to that of gorgeous clothes for human beings. Good label design will make your bottled water more outstanding and successful in the market.

There are usually three types of labels for the production of bottled water.

- Shrink sleeve label.

- OPP hot glue label.

- Self-adhesive sticky label.

When you tell our team of engineers about your bottle type and the required production capacity, we will recommend the most suitable bottle water machine model to you.

The price of bottle water production machine is usually related to three aspects: the degree of automation, bottle size and material, and the required production capacity.

If your budget is limited, you can start with a low-capacity water bottle filling machine.

Our smallest fully automatic bottle washing filling capping monoblock is suitable for a start. It can produce PET bottled water from 300ml to 2L sizes. Whether it is bottled mineral water production, pure water production, or flavored water production, it can meet the requirements. The price of this machine is usually around $14,000.

If you consider a semi-automatic water filling equipment, the price will be as low as $2,000.

But the semi-automatic machine capacity is relatively low, but also need to manually place empty bottles, and only have water filling function, but also need to be equipped with a separate bottle washing machine and a separate capping machine.

If you need a high-output fully automatic bottling machine, the price will be higher. According to the configuration of electrical appliances, the price will vary.

So don’t always ask ‘how much’, please tell us your requirement so that we can custom the best water bottle filler machine and the best offer for you.

The core component of the filling machine is the filling valve. Liquids with different viscosity need to use different filling technology. Because the viscosity of water is very low, we choose to be suitable for filling equipment with low viscosity.

Mechanical gravity filler.

After the filling valve is opened, the water is automatically filled into the bottle by gravity, which is the best choice for the water filling factory with reasonable structure and stable operation. It is the first choice for low viscosity liquid products.

Vacuum negative pressure filler.

Some liquids produce foam in the filling process, so vacuum technology is needed to eliminate foam, such as in the process of filling mouthwash liquid.

Flowmeter filler.

The biggest advantage of using flowmeter filling technology is fast filling speed, and can achieve non-contact filling to avoid bottle mouth pollution. It can be applied to medium and low viscosity liquids, such as mineral water filling, drinking water filling, edible oil filling and so on.

Our machine is designed with a lot of general parts, so you can also buy the same type of parts in the local market and replace them, which greatly reduces your use and maintenance costs.

Our machines are manufactured in clean and tidy factories, but also in order to better handle your bottled aquatic products. If you have not only low viscosity products like water, but also other viscous liquids that need to be bottled, we also have mature bottling solutions.

So please feel free to give us your next order for the bottling machine.

We will have some standard models of water bottle filling equipment, such as CGF8-8-3, CGF24-24-8, QGF-600 and so on. Different models represent different production capacity and different bottle types. Due to the ever-changing specifications of our customers’ bottles, our machines are all manufactured according to orders, customized according to the customer’s bottle diameter, height and type.

When some customers ask, do you have water bottling machine in stock, our answer is no.

But as long as you send us a sample of your bottle or provide bottle design drawings, we can manufacture a water bottling machine for your bottle within 25 working days.

In addition, please do not compress our machine manufacturing time, reasonable manufacturing time can ensure the stability of your operation after receiving the machine.

Matters needing attention during maintenance:

- The machine must be thoroughly cleaned after each production. Water should not contact with motors or electrical components when cleaning, and it is not appropriate to put water into gears and bearings when cleaning.

- All seals and residual liquid on the paint surface should be scrubbed clean.

- In the maintenance of parts, try not to damage the outer surface of parts, seals and non-metallic parts.

- Where grease needs to be filled in advance, the grease should be filled in the maintenance process.

- Repair and inspection of the machine must be disconnected from power supply.

- Regularly check the material, flushing water, compressed gas pipeline for leakage, and repair in time.

- Do not use toxic drugs, organic solvents and other cleaning equipment surface.

- The disassembly of the machine must be carried out by a professional and use reasonable lifting equipment.

- Electrical equipment should always be kept clean to prevent oil, water and dust from soaking.

- Check the grounding wire of the machine and turn on the power supply only after checking it correctly. The manufacturing unit is not responsible for the damage caused by improper connection of the ground wire.

- The electronic components used in this machine, such as PLC, frequency converter, touch screen and flow meter, have been set up in the factory and cannot be changed by themselves.

- The maintenance of spare parts (such as motor, reducer) should be in accordance with the manufacturer’s instructions, if necessary, professional manufacturers can be asked to assist in maintenance.