Full automatic sterilization and cooling tunnel & bottle warmer

It is applied in the filling production line of fruit juice (tea), as a kind of tunnel Pasteur sterilization for the treatment of filled containers.

| Processing type | Bottle cooling and warming machine |

|---|---|

| Bottle type | Various bottes |

| Working temperature | Room temperature |

| Heating manner | Steam heating and electric heating |

| Temperature zone | 4 sections / customize |

Details About Full automatic sterilization and cooling tunnel & bottle warmer

Fill the untreated product in the container, seal the container, then through the conveying belt, the container enter the tunnel Pasteur sterilization and spraying cooling machine. Within the different temperature zones, the container is sprayed by the water with different temperatures, which is the sterilization phrase and cooling phrase. It adopts the principle that the water sprayed on the cooler container will turn hotter; the hotter water can be used to cool the sterilized hotter containers, making the container gradually cool down. In this way, it can avoid the loss of taste caused by overheat and prevent cracking or deformation of the containers because of the sudden change of the thermal stress. The interconnection of the heating zones and cooling zones will better recycle the energy — this is the energy regeneration principle. The tunnel Pasteur sterilizer makes full use of the heat balance principle and only consumes limited resources in sterilization zone.

Features:

1. Several temperature zones will be designed basing on production capacity, processing requirement etc;

2, All the pumps are Nanfang pump;

3, The top plate can be removed for easy maintainence;

4, There is recycling tank in the bottom for saving energy;

5, Two heating manners: steam heating & electric heating;

6, Suitable for juice / tea filling line, hot filling line, beer filling line, soft drink filling line etc;

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

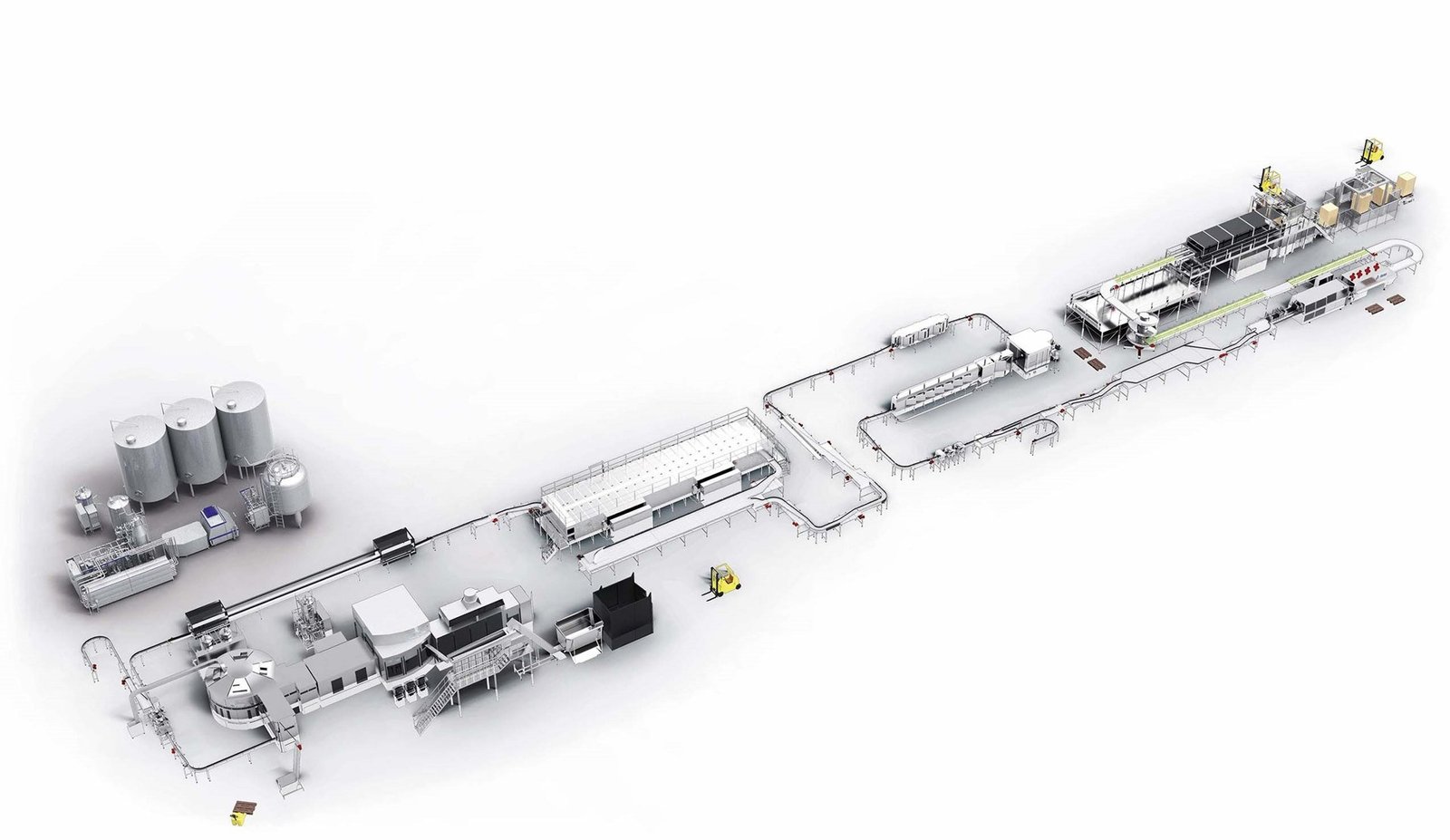

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.