Details About Juice bottling machine beverage hot filling machine supplier

At present, there are two main filling methods for juice bottling, one is hot filling (filling temperature 85 ℃ to 92 ℃), and the other is ultra-clean medium temperature filling machine (filling temperature 50 ℃-60 ℃).

Juice hot filling is commonly used in beverages because the process is mature and the equipment investment is relatively low.

If this is your first time to make bottled juice, our advice is to start with hot filling machines.

Automatic hot filling machines are easy to operate, and the stability of the product will be better.

After you have accumulated enough experience, you can try the ultra-clean medium-temperature filling production line.

If you want to import production lines from China, Festa will be the best choice for your project. We have 14 years experience in the juice bottling line manufacturing. , you can get the complete production line from A to Z in one factory.

Drop us an email or Press “Add to Quote” button to send us an order now!

Main features:

- The equipment has the advantages of compact structure, perfect control system, convenient operation and high degree of automation.

- The parts contact with fruit juice are all made of S/S316.

- The use of high-precision, high-speed filling valve, accurate liquid level without liquid loss to ensure excellent filling quality.

- The capping head adopts a constant torque device to ensure the sealing quality.

- Configure CIP cleaning system to ensure the cleanliness of the filling system of the whole machine.

- Equipped with perfect overload protection device, which can effectively protect machinery, equipment and operators.

- The control system has the functions of automatic monitoring of material temperature, detection of missing cover, self-stop of card bottle, output counting and so on.

- The bottle washing system adopts high efficiency spray nozzle, which can be cleaned to every part of the bottle.

- The main engine adopts ABB brand, and the bearing is equipped with automatic lubricating oil system.

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

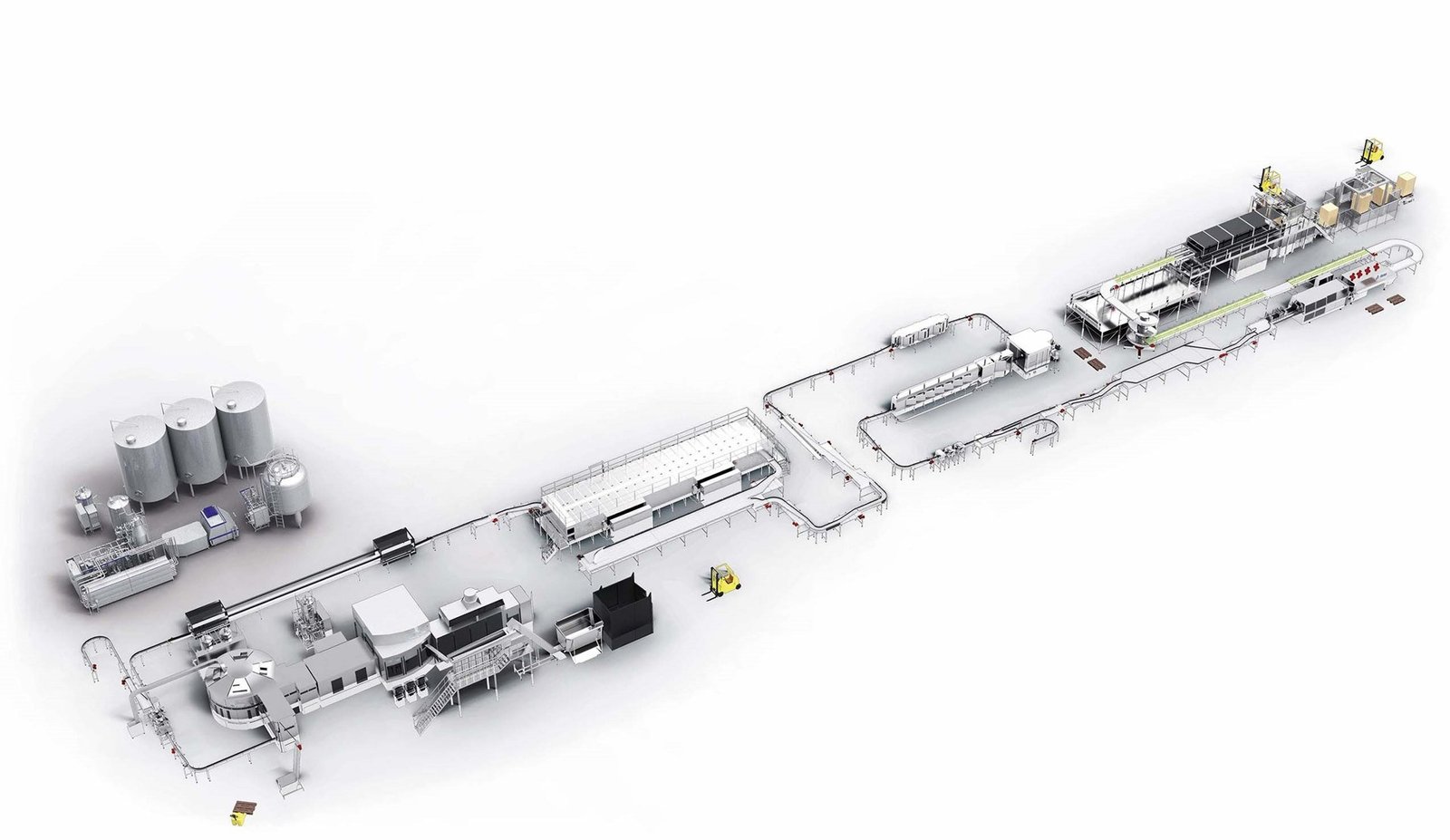

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.