FST-9000 Automatic PET Bottle Stretch Blow Molding Machine

- Stable and accurate running at high speed, adopt more stable and advanced microcomputer PLC control system.

- Production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

- Suitable for flexible production of quantity and various bottle shape, wide range of applications, meet customer needs.

- Manual and automatic methods of operation, human-machine interface control, simple operation.

- Servo transmission system, high positioning accuracy, fast speed stability and good reliability.

- Less than 0.2% scrap rate for finished bottle .

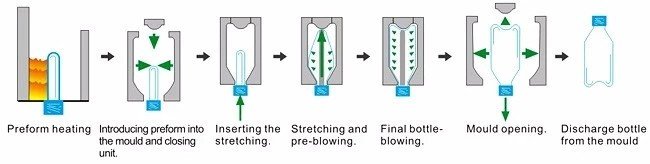

Details About FST-9000 Automatic PET Bottle Stretch Blow Molding Machine

Servo transmission system

High positioning accuracy, fast speed and stability, good reliability. Gas circuit design will divide action and blowing into three parts to meet the needs of different pressure for blowing bottles and movement; Adopt high pressure and double crank arm link locking, strong clamping force.

Adopt infrared lamp heating

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; Heating lamp, reflector width and height can be adjusted to suit preform heating of different structure, with automatic temperature-removal device to ensure the constant temperature of oven.

Auto-loader

Auto-loader improves working efficiency, accurate transportation, reliable and durable, raw materials are completely free of moisture, pollution, foreign matter, and loss during feeding process. Realize transportation process of feeding process, avoid danger of high-altitude feeding, reduce labor intensity and increase production efficiency.

Intelligent Human-Machine Interface

1.Human-machine interface control, easy operate and monitor.

2.Live production information supervise, auto record production data everyday

3.Failure warning and troubleshooting.

| Model | FST-9000 | |

| Bottle type specification | Cavity | 6 |

| Theory output: BPH | 8000-9000 | |

| Max. volum | 2L | |

| Bottle mouth maximum overall diameter | 28-38mm | |

| Bottle biggest diameter | 100mm | |

| Bottle maximum height | 330mm | |

| Power specification | Light tube quantity | 72pcs |

| Light tube power | 1.5KW | |

| Maximum heating power | 108KW | |

| All electric machine installation | 110KW | |

| Actual consumption | 40%–60% | |

| Air pressure specification | Work pressure | 7-9kg/cm2 |

| Low-pressure gas consumption | 1600L/min | |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher -pressure gas consumption | 8000Ltr/min | |

| Air pressure specification | Work pressure | 5-6 kg/cm2 |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Forzen water flow | 138L/min | |

| Machine specification | Machine size | 6.5×2.0x1.9 |

| Machine weight | 5.5ton | |

After Sale Sercive

1.Installation, debug

We will arrange seasoned technician for debug and test production at the same time make the equipment reach the rated producing

capacity of the line.

2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and

operation of equipment. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures.

3.the sample service

1’We can send you the video of the running machine.

2’You are welcome to come to visit our factory,and see the machine running.

4.We can design the machines according your requirements,at the same time we will give you our professional suggestion,as you know,we have been in this industry for 12 years.

5.well-trained & experienced staff are to answer all your inquiries in English and Chinese

6 .12 Months guarantee and life-long technical support.

7.Your business relationship with us will be confidential to any third party.

8. Good after-sale service offered, please get back to us if you got any questions.

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

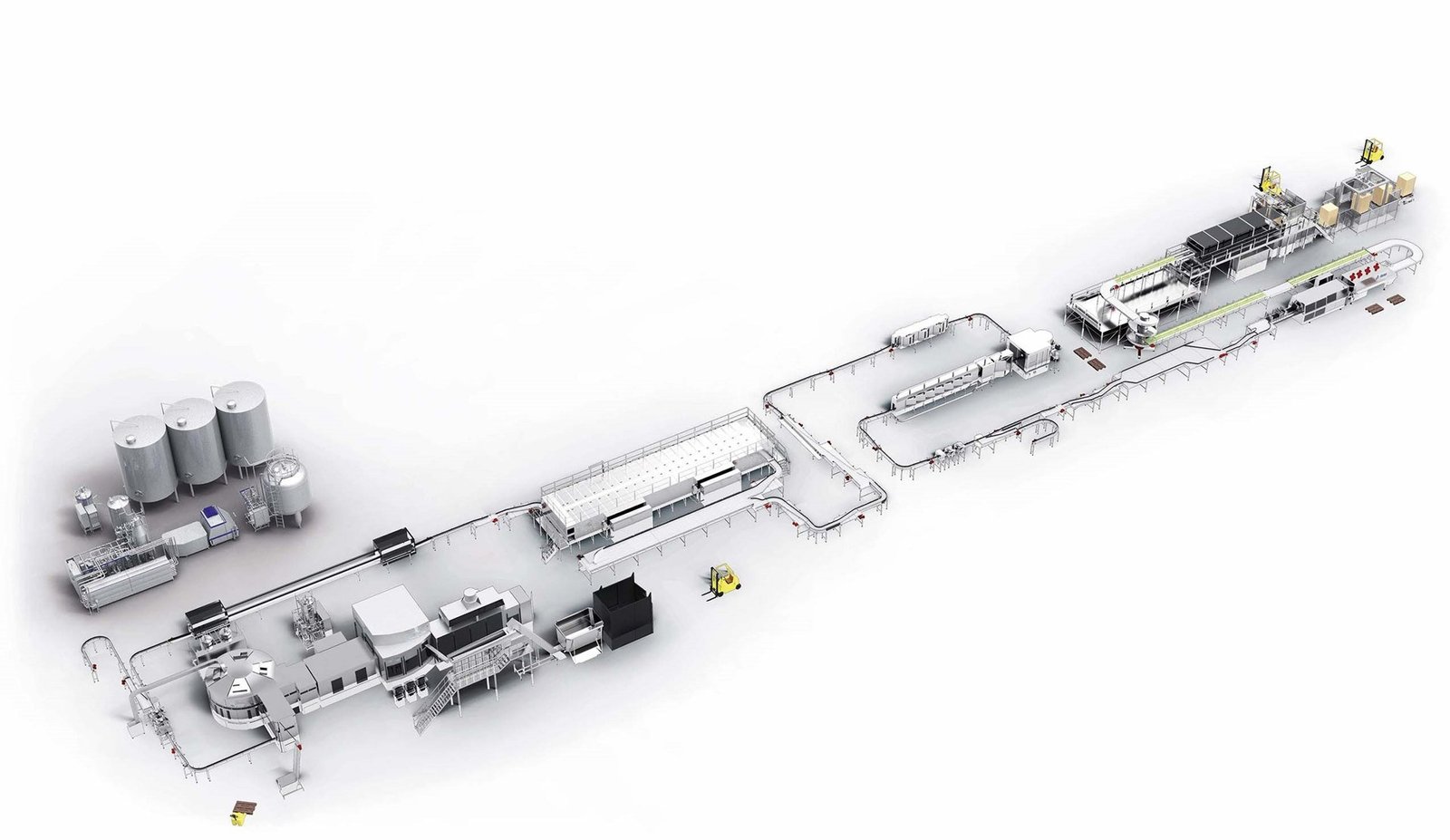

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.