PET Bottle Blower Machine of 5liter FD-5L4

Production capacity: 2500-3000BPH

Machine control: PLC control

Number of mold cavity: Four

PET Bottle size: One gallon, 4liter and 5liter

Benefit of FESTA FD-5L4 5liter PET Bottle Machine

If customers need a high-speed stretch blowing machine for the production of 5-liter PET bottles, then our FD-5L2 is your best choice. It can produce up to 3000 high-quality empty bottles per hour to help you win the market. We have prepared sufficient equipment parts as inventory, so we can quickly supply spare parts of the bottle blowing machine at any time.

In order to ensure that the customer technical personnel can correctly grasp the performance, operation and maintenance procedures of the equipment, in addition to the normal installation site technical training, we can also hold all kinds of professional training in the FESTA factory, which will help users to master the technology faster and more comprehensively.

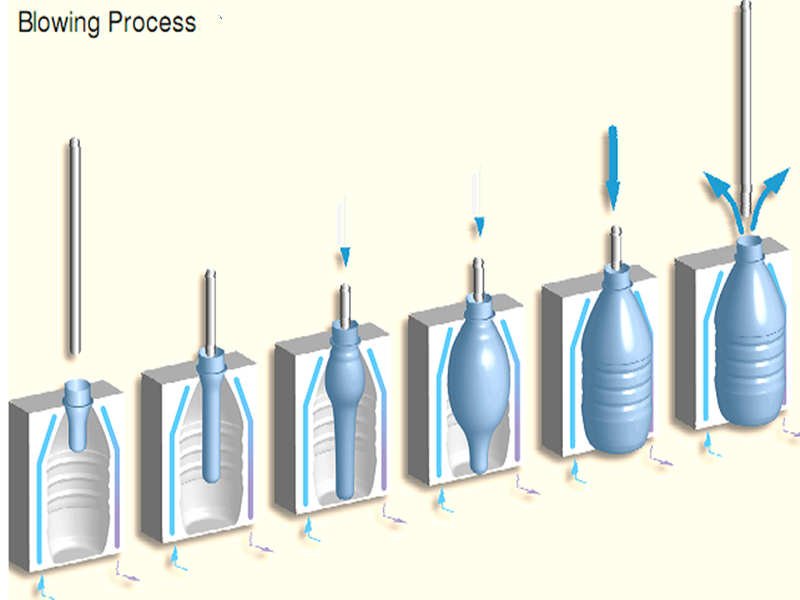

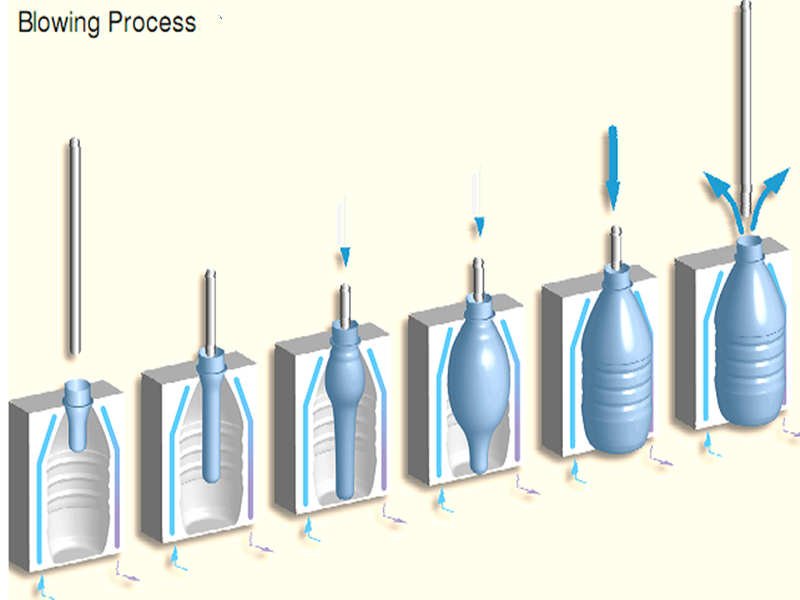

- Mold system: using high-pressure mold locking technology, no mold expansion phenomenon, and the mold closing line is fine.

- The mold adopts drawer structure, and four fixed pull rods are used on the back plate of the mold, which can be easily replaced in half an hour.

- Pull and blow system: the cycle time of one blow and two blowing can be adjusted, and each pull rod can be adjusted separately according to different tube embryos and different bottle types, with high flexibility.

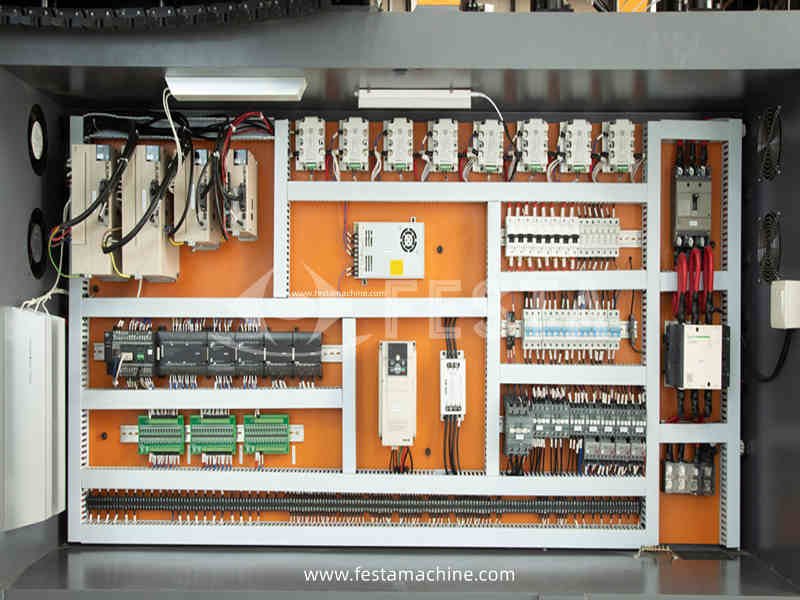

- Electronic control system: pneumatic and electrical components are well-known international brands, touch screen control system is easy to operate, with perfect monitoring and induction settings, with fault diagnosis function, automatic calculation report function, grasp the production efficiency of each shift.

- Cooling / chilled water circulation system: there is a cooling channel under the heating box, which is used to block the heat of the lamp tube when the bottle embryo is heated to protect the tooth mouth from deformation.

- Chilled water leads to the mold, which can quickly cool the mold and improve the production efficiency of the whole machine.

Compose. | Item. | Parameter |

Bottle blowing part. | Number of mold cavity. | 4 |

Bottle outlet part height (lower part of the supporting ring). | 1.4m | |

Heating part. | Heating unit. | 8 |

Number of heating lamp layers. | 7 | |

Electric parameter. | Voltage. | 380V |

Frequency. | 50/60Hz | |

Total installed power. | Total power. | 80kw |

Average operating energy consumption. | Power. | 25-35kw/h |

Air source | Low pressure compressed air pressure. | 0.7~0.8MPa |

Low pressure compressed air consumption. | 2.0m3/min | |

High pressure compressed air pressure. | 10m3/min 3.0MPa | |

Weight. | Mainframe. | 4T |

Dimensions of equipment. | Host (L × W × H). | 8500mm×1850mm×2200mm |

Embryo machine (L × W × H). | 1800mm×1800mm×2300mm | |

Preform size | Flask embryo height. | ≤200mm |

Bottle germ diameter. | ¢40mm~¢55mm | |

Bottle size | Diameter range of round bottle. | ¢120mm~¢200mm |

Bottle size (diagonal). | 200 | |

Height below the supporting ring. | ≤400mm | |

Capacity range | 2L~5L | |

Preform material | PET | |

Production capacity | 2500-3000BPH | |