Your Best PET Blow Molding Machine Supplier

- Rich experience in PET bottle making machine industry

- Free bottle shape design: tell us your idea and we will design your favorite bottle for free

- Adopt the most stable parts brand to ensure the production efficiency

- Production Capacity: 2000-36000BPH

- Bottle Size: 200ml-20Liter

Customized Options, Strong Compatibility Bottle Blowing Machine

FESTA offers a range of PET bottle solutions, whether you are producing PET mineral water bottles, carbonated drink bottles, hot filling juice bottles or edible oil bottles, we can provide you with one-stop service and equipment.

From 200ml to 20L bottles, from round bottles to square bottles, we have rich experience in making bottle blowing machines to meet your needs.

Linear Blow Molding Machine

It is our smallest fully-auto PET bottle blowing machine, it is mainly used to produce small PET bottle for water bottling factory, CSD bottling plant. It can produce up to 2000 empty PET bottles per hour (based on 500ml), which is the best choice to replace the semi-automatic bottle blowing machine. Save energy consumption, save labor, safer and more efficient.

- Production Capacity: 1,800-2,000 bottles per hour

- Mould Quantity: 2 cavity

- Dimension: 1900×1580×1930mmmm

The machine can produce up to 4000 PET bottles per hour, and connect with 3 in 1 water filling machine by air conveyor, automatically transport the produced bottles to the water filling machine, which can realize continuous production and effectively reduce a lot of space needed for empty bottle storage.

- Production Capacity: 3,500-4,000 bottles per hour

- Mould Quantity: 4 cavity

- Dimension:3400×1600×2300mmmm

It can produce 5,000-6,000 plastic bottles per hour and is compatible with 300ml to 1.5L bottle capacity. Wide range of application, low energy consumption, can be used in different liquid packaging plants, such as water bottling plant, carbonated bottling plant and so on.

- Production Capacity: 5,000-6,000 bottles per hour

- Mould Quantity: 6 cavity

- Dimension: 4600×1850×1900mm

Adopt linear bottle blowing machine technology, 6-cavity bottle blowing mold, full servo motor control system, production capacity up to 8000-9000BPH, maximum compatibility up to 1.5L PET bottle.

- Production Capacity: 8,000-9,000 bottles per hour

- Mould Quantity: 6 cavity

- Dimension: 4500×2400×2300mm

The machine is usually used with a fully automatic water bottling machine and is connected to the filling machine through a high-speed bottle air conveyor, no need to purchase bottle unscrambler separately, reducing energy consumption and investment costs.

- Production Capacity: 10,000-12,000 bottles per hour

- Mould Quantity: 9 cavity

- Dimension: 5500×2600×2600mm

Rotary Blow Molding Machine

RBM-6 is a small rotary bottle blowing machine specially developed by FESTA according to the market demand. Compared with the linear bottle blowing machine with the same production capacity, it has many advantages, such as saving energy consumption, saving space, saving investment cost, saving labor cost and so on.

- Production Capacity: 10,000-12,000 bottles per hour

- Mould Quantity: 6 cavity

- Bottle Volume Range: 0.25-2Liter

The machine can produce up to 24000 empty PET bottles per hour, which can be combined with filler capper to form combi, or can be used as bottle making machine alone. Flexible application scenarios make RBM-10 a star product of FESTA.

- Production Capacity: 22,000-24,000 bottles per hour

- Mould Quantity: 10 cavity

- Bottle Volume Range: 250ml-2000ml

High-speed bottled water and carbonated beverage production lines usually only consider rotary stretch blow molding machines. FESTA RBM-16 can produce 36,000 PET bottles per hour, servo drive, servo stretching, high efficiency preform heating system, efficient high pressure gas recovery valve set. The whole machine runs at high speed, stable and reliable.

- Production Capacity: 33,000-36,000 bottles per hour

- Mould Quantity: 16 cavity

- Bottle Volume Range: 250ml-2L

PET Jar Blow Molding Machine

The machine adopts servo drive and microcomputer control, and can produce two Jar bottles at one time. It is widely used in food, medicine, beverage and other industries.

- Production Capacity: 1500-2000 per hour

- Mould Quantity:2 cavity

- Dimension: 2300X1800X2200mm

The machine adopts automatic PLC control and has a 4-cavity bottle blowing mold with a production capacity of 2500-3200BPH. It is the preferred PET Jar production equipment for large and medium-sized food and beverage enterprises.

- Production Capacity: 2500-3200 per hour

- Mould Quantity: 4 cavity

- Dimension: 4200X2000X2200mm

Semi-auto PET Bottle Blowing Machine

FESTA semi-automatic bottle blowing machine has the advantages of low price, stable quality and good compatibility. If you plan to produce PET empty bottles for your water bottling plant, this will be the easiest bottle making machine for you to master.

- Production Capacity: 600-1000 bottles per hour

- Mould Quantity: 2 cavity

- Bottle Volume Range: 0.25-1.5Liter

Our semi-automatic 5-gallon bottle blowing machine has been widely praised by our customers. compared to buying 5-gallon empty barrels directly on the market, purchasing a 5-gallon bottle blowing machine can greatly save your production costs and empty barrel transportation costs.

- Production Capacity: 60-80 bottles per hour

- Mould Quantity: One cavity

- Bottle Volume Range: 3 Gallon & 5 Gallon

In recent years, 5 liter large bottles of drinking water are becoming more and more popular among consumers, so many clients chose our semi-automatic 5 liter bottle blowing machine. You don’t need a lot of investment to start producing your own 5-liter bottles. It meets the needs of small filling factories.

- Production Capacity: 300-400 bottles per hour

- Mould Quantity: One cavity

- Bottle Volume Range: 3 liter, 5 liter PET Bottle

Related Equipment of PET Blow Machine and PET Filling Line

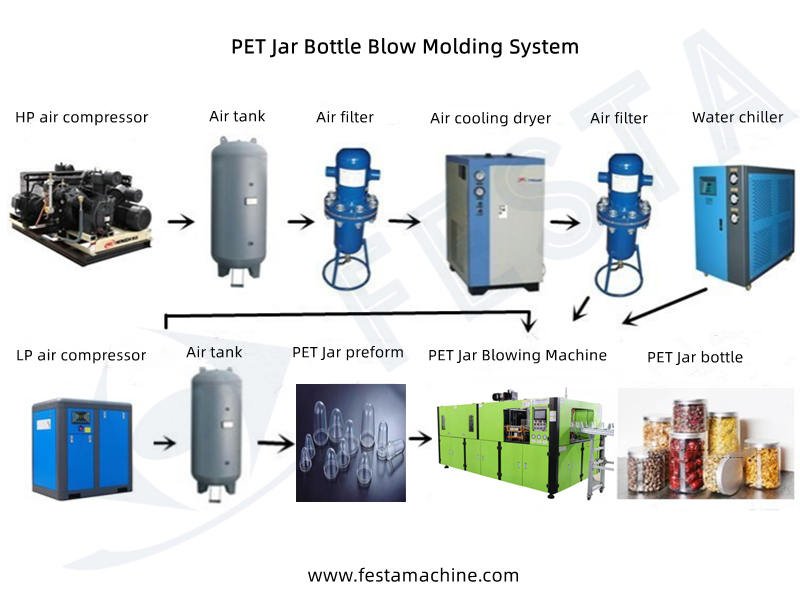

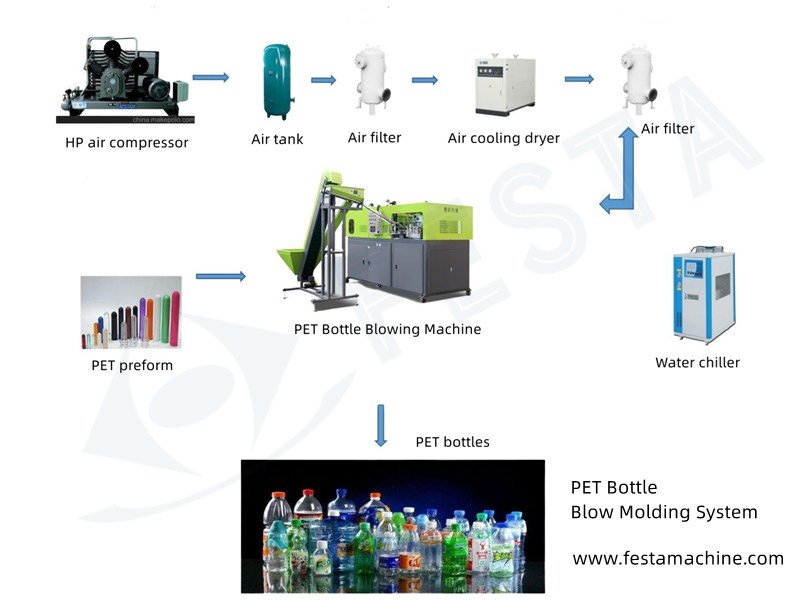

One-stop Solution for the PET Blow Molding System

We not only manufacture high quality PET blow molding machine, but also provide auxiliary equipment of blow molding system, such as air compressor system, cold water machine system, filter system, blow molding mold and so on. Just tell us your needs and we will tailor a complete set of PET bottle blowing system for you. Our experienced engineers will adjust your machine to the best condition so that you don’t have to worry about using it.

Provide PET Blow Molding Machines with Different Technologies

We have a rich PET blow machine product line. Not only can provide semi-automatic blow molding machine, fully automatic blow molding machine. We can also manufacture rotary stretch blow molding machine and linear PET blow molding machine. For the increasingly diversified development of bottle types, we can provide not only small bottle blow molding machines, but also 5L blow moulding machines, 20L bottle making machines, 5 gallon blow molding machines and so on.

FESTA Provide PET Bottle Blowing Filling Capping Combiblock

Now the market demand for high-speed production line is increasing, the traditional linear blow molding machine link automatic filling machine has been unable to meet the development trend. FESTA is one of the few suppliers that can provide PET bottle blowing filling capping combiblock solutions. Combi can be used in PET water, PET carbonated beverages, PET fruit juice drinks and other industries. Mainly used in 12000BPH to 48000BPH high-speed production line.

FESTA PET Bottle Stretch Blow Molding Machine for Sale

The performance of PET blow machine is usually related to the technology accumulation of suppliers and the quality of parts used. FESTA promises that all blow molding machines use well-known brand electrical components and carry out assembly, commissioning and other work under the guidance of experienced engineers. Ensure that each blow molding machine achieves the best performance before delivery.

Visit Our Factory to See PET Blow Machine Manufacturing

We based in China, we have a big factory to produce PET Bottle Making Machine

The Ultimate Buying Guide for PET Blow Machine

PET blow machine refers to the machine that blows PET bottles. The most simple explanation is that the finished PET bottles can be blown into bottles by certain technological means. The bottle blowing machine is convenient and fast, and has a large amount of formation. after it appeared, it replaced most of the manual bottle blowing and was adopted by most beverage enterprises. We also call it PET bottle blowing machine or PET bottle blow molding machine. PET bottles are widely used in food packaging, pure water and mineral water filling, fruit juice filling, soft drink filling and other fields. Its excellent economy has won very good market feedback. The birth of PET bottle blow machine has also greatly promoted the rapid development of the beverage and bottled water industry.

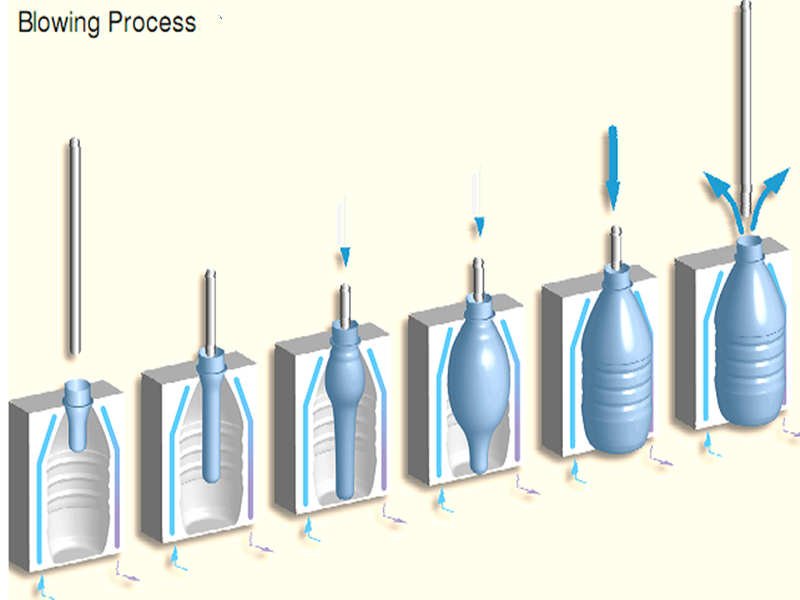

Most PET bottle blowing machines are two-step bottle blowing process, that is, plastic resin must be made into PET bottle preform before blowing. Nowadays, the commonly used material is PET, which is environmentally friendly plastic. The PET preform is heated to the softening state and placed in the open mold. After closing the mold, compressed air is injected into the preform immediately, so that the PET preform is inflated and clings to the inner wall of the mold. After cooling and demoulding, various PET empty bottles are obtained.

Pre-heating.

The PET preform is irradiated through an infrared high temperature lamp tube to heat and soften the body part of the preform. In order to maintain the shape of the bottle mouth, the preform neck does not need to be heated, so it needs a certain cooling device to cool it.

Blow bottle forming.

In this stage, the preheated bottle preform is placed in the blow mold, which is inflated under high pressure, and the bottle preform is blown into the required bottle.

Bottle blowing machines on the market are generally divided into fully automatic and semi-automatic. The fully automatic bottle blowing machine completes the two operations of bottle blowing together through the operation of the manipulator, eliminating the process of putting the preheated preform into the blowing mold. The rate of production is greatly accelerated, and of course the price is higher than that of semi-automatic ones.

How to choose the type of bottle blowing machine you need must also be the topic that everyone pays the most attention to. Generally speaking, choose the model of the bottle blowing machine according to the products you need. For different manufacturers, the general concern is the number of cavities, the size of the bottle volume, and the output per hour. It is critical to choose the model that meets your needs according to your own needs.

For example, suppose you want to buy a PET bottle blowing machine for your own water bottling plant, then you have to determine how many bottle sizes you have, such as 500ml, 1L, 1.5L, etc. Different bottle sizes need separate bottle moulds to produce. Many customers think that one bottle blower and one mould can produce all bottle types, which is wrong.

Under normal circumstances, PET bottles less than 2L can be produced on the same bottle blowing machine.

PET bottles of sizes ranging from one gallon to 15 liters need a separate high-capacity bottle blower.

If it is a 5-gallon bottle used in the water dispenser, it is a different kind of bottle blowing machine.

After determining the bottle type, you can tell the manufacturer the production capacity you need (how many bottles per hour). The greater the production capacity of the machine, the higher the degree of automation and the higher the price.

The PET bottle blowing machine accounts for a large proportion of the investment in the entire production line, so you need to prepare a sufficient budget.

If you need a stable, cost-effective PET bottle blowing machine, you can contact us and we will customize a solution according to your needs

(1) The moving parts must be lubricated once before each shift is started. (manipulator, manipulator guide, opening and closing die guide).

(2) The arm swing can be added once every 3 to 4 days. The big chain and small chain of the heater can be used once a month. Always check whether the main engine reducer and heater reducer are short of oil. The main engine bearing can be added once every 3 months.

(3) Before production, check whether the moving parts are firm, whether the screws are loose and fall off, especially where the impact force is strong, and whether the belt transmission part is abnormal.

(4) Check whether the high pressure gas source, low pressure gas source, power supply and water source are normal.

(5) Check whether the emergency stop switch, safety door switch and protective device check whether the switch is normal.

(6) Check whether the heating head is in the preform and whether the preform is working normally. If the preform is not in place, the nut of the preform pressing device can be adjusted.

(7) Check whether the lamp tube is damaged or broken. It should be replaced in time.

(8) Check whether the pneumatic components are leaking and whether the action is sensitive.

(9) Check whether the triplet is abnormal air leakage, whether it is blocked, and whether the water storage capacity of the water cup is too full.

(10) If there is anything abnormal in the electromechanical solenoid valve of the fully automatic bottle blowing machine, it should be cleaned in time (3.5 million per bottle blowing).

According to the degree of automation, there are fully automatic PET bottle blowing machine and semi-automatic PET bottle blowing machine.

According to the arrangement of bottle blowing moulds, it can be divided into linear PET stretch blowing machine and rotary PET stretch blowing machine.

According to the size of the bottle, it can be divided into small bottle blowing machine, 1 liter PET blow machine, 5 liter bottle blow molding machine equipment, 20 liter PET bottle blower, 5 gallon bottle blower machine, PET jar bottle blowing machine, etc.

According to the number of mold cavities, it can be divided into two-cavity bottle blower, four-cavity bottle blow molding machine, six-cavity PET blowing equipment, 8-cavity stretch blow molding machine and so on.

The price of PET bottle blowing machine is related to many factors, such as bottle size, production capacity, degree of automation and so on.

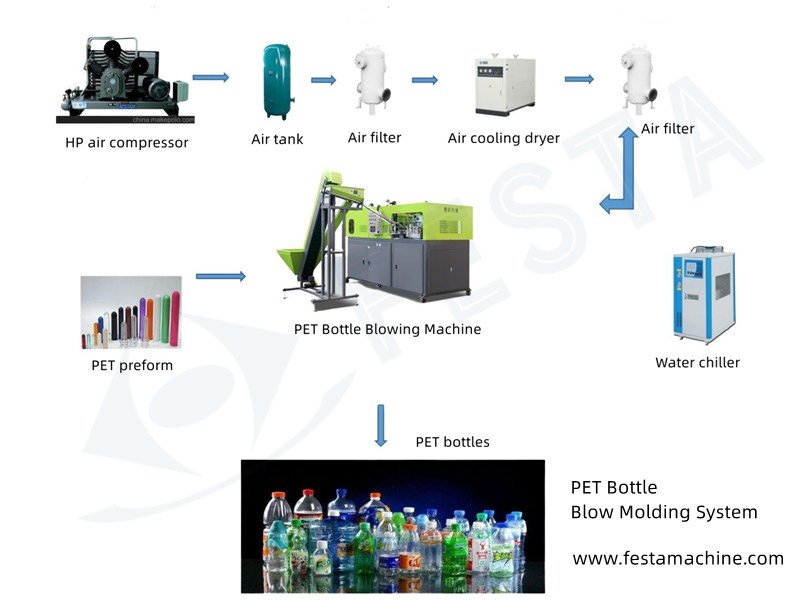

In water bottling plants, juice bottling plants, PET bottle blowing machine is a very special existence. It cannot run independently and requires other auxiliary equipment to be connected together to complete the bottle blowing process.

Rather than buying a bottle blowing machine, you are actually buying a PET bottle blowing system, which includes a bottle blowing machine, bottle preform heater, high pressure air compressor, high pressure air storage tank, water chiller, air cooling dryer, air filter, bottle blowing mold and connecting pipes, etc. The following figure is a schematic diagram of a conventional linear stretch bottle blowing machine system.

The price of the whole PET bottle blowing machine system will be relatively expensive, accounting for a high proportion of the entire production line investment, which requires you to plan in advance.

The smallest semi-automatic PET bottle blowing system also requires a price of more than $10,000 (excluding packaging freight). If it is a high-speed rotary stretch blowing machine system, it requires an investment of millions of dollars.

Although it costs more to buy a PET blow molding system, you can control the quality and supply of the bottle, and you can connect it directly to the filling line through the air conveyor.

Reduce production costs and increase the input-output ratio. In fact, when the market is good enough, you can quickly recoup the investment in bottle blowing machines and take the lead in the market.

As a China PET bottle blowing machine manufacturer, we are well aware of customers’ pain points and the most real needs of customers.

High-efficient preform supply system:

Fully-automatic preform-unscrambled and preform-loading structure, which no only achieve faster and high-efficient preform-unscrambled and preform-loading, but also improving the stability of the whole machine running process. There is a sensor installed in the preform down-track, when the preform track lack of preform, the preform will be delivered into the preform-unscrambled system from the hopper automatically. And the one-way preform-inserted design can solve the preform-blocked and preform abrasion problem.

Servo preform-divided system:

Preform are divided equidistance by servo motor. The stroke and speed of servo motor are easy adjusted through the HMI. All complicated process are done by digitization, safe, fast and accurate. Compare with the traditional server-ways preform-divided, cylinder type preform-divided etc, the servo motor control one-way preform-divided, speed is more faster and position is more accurate.

Intelligent heating system:

Preform are heated by infrared lamps which make the preform stretching more equably and higher transparency. With the help of imported reflective mirror aluminum plate, the heat energy of lamps are took full advantage of; heating time is shorter ; lower power consumption and improving the production capacity. The temperature of each lamp of every layer can be adjusted up and down, forward and backward individuality according to different preforms. Intelligent ventilation system keeps the oven temperature inside constantly.

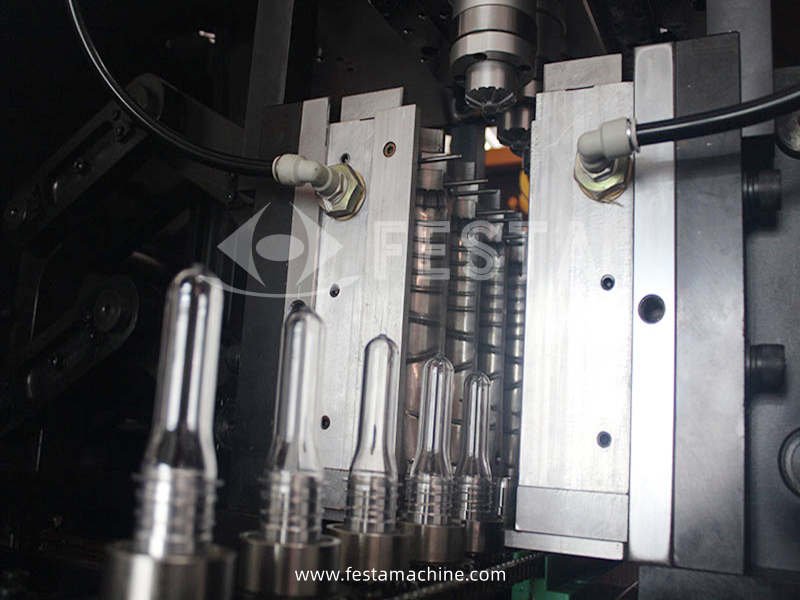

Servo mold-clamping system:

The mold-clamping system is drove by servo motor and mechanical connecting rods. The molds and bottom mold are clamped synchronously through servo motor. High-pressure mold-locked by the high-pressure pressurized plates behind the mold framework which can reduce visibility of the bottle clamping line effectively and ensure the bottle quality. Drawer type mold structure design, easy mold exchange, skillful engineer can finish the mold exchange in half an hour.

Servo stretching system:

The servo motor drives the gear rack to stretching. With our developed photoelectric and mechanical limits these two double security, the stretching rods can not hit the bottom mold. The pre-blowing and 2nd blowing cycle time can be adjusted individually in the HMI according to different preform and bottle design. The stretching rods can be adjusted automatically, high flexibility.

HMI operation system:

Our blow molders are high intelligence, easy operation. Chinese-English language color touch screen, with perfect monitoring sense setting, troubleshooting display, auto calculating report, memory store etc. function. You can control the machine production situation all the time.

Chilled/cooling water recycle system

Our self-developed heating bases cooling setting ensure the heating bases cooling effect after the bottle-blowing. There are coolant gallery installed inside the oven which use to cut off the heat from the lamps during the preform-heating. The cooling air system under the coolant gallery protests the neck finish from deformation. The chilled water connect to the mold, cool down the mold rapidly and improve the machine production efficiency.

Standardize spare parts and quality electric components:

Most of our spare parts meet the international production standard. The standard parts are produced in bulk in our CNC machining center and put into use after strictly inspection by our QC department. These high quality standardize parts ensure the stability and reliably of our machines and reduce the maintenance cost. The motors, PLC, cylinder, solenoid valves, electric parts and blowing valves, key components of our machines are use quality products of China and international famous brands.

No. | Name | Origin | Brand |

Electric/control component | |||

1 | Mold-clamping servo motor | Japan | YASKAWA |

2 | Stretching servo motor | ||

3 | Main transmission servo motor | ||

4 | Preform-divided serve motor | ||

5 | Servo driver button | ||

6 | Air switch | France | SCHNEIDER (TE) |

7 | Contactor | ||

8 | Intermediate relay | Japan | OMRON |

9 | PLC | ||

10 | PLC expand module | ||

11 | Touch screen | Taiwan | Panel |

Valves/adaptor | |||

1 | Pre-blowing valve | USA | PARKER |

2 | 2nd blowing valve | ||

3 | Exhaust valve | ||

4 | One-way valve | ||

5 | Pressurizing mold-locked motion valve | ||

6 | Step chain | Taiwan | KMC |

7 | Mold-clamping lead rail | Taiwan | ABBA |

No. | Item | Complete time |

| Bottle drawing and order place | 2 days after signing contract and receiving the deposit. |

| Machine production | 6 weeks |

| Machine testing | 1 week |

| Machine FAT and delivery preparation | 1 day |

| Machine delivery | 1 day |

| Machine installation | First week |

| Water, electricity and air installation (need to cooperate with customer’s engineers) | |

| Machine testing | |

| Trial production | |

| Bottle inspection | |

| Machine acceptance check | Second week |

| Operator training, key, technical documents handover |

The main structure is usually welded by high-strength carbon steel, and the outer surface is painted with strong wear resistance and good corrosion resistance. The machine is equipped with a large number of sensor components (temperature sensor, pressure sensor), proximity switch, cylinder, solenoid valve, servo motor, servo controller, PLC, touch screen, pump, high pressure valve group, low pressure valve group, compressed air filter, water filter and so on.

Therefore, PET bottle blowing machine is a kind of automation equipment with high electrification integration, which explains why the price of bottle blowing machine equipment is relatively high and more important.

FESTA in the stretch bottle blowing machine parts selection follows high standards, the selection of top brands, to ensure the quality and stability of the machine. Due to the use of a large number of general components, it also greatly reduces the cost of purchasing spare parts for customers in the later stage.

High pressure air compressor.

It is used to provide the high pressure compressed air needed by the PET bottle blowing machine, and the conventional bottle blowing pressure is 3 Mpa.

Compressed air storage tank.

It is used to temporarily store the compressed air produced by the high-pressure air compressor to keep the pressure constant.

Air cooling dryer.

Used for cooling and drying compressed air to meet bottle blowing requirements.

Water chiller.

It is used to cool the mold of PET bottle blowing machine to ensure the stability of bottle forming.

Air filter.

Filter compressed air, remove impurities and oil stains, and avoid contamination of blown bottles.

Bottle blowing mould.

By changing the bottle blowing mold, empty PET bottles with different capacities and shapes can be produced on the same bottle blowing machine.

There are two kinds of materials for bottle blowing die: ordinary steel and aviation aluminum.