What is Homogenizer?

Homogenization purpose: Homogenization purpose is the process of ultra-fine powdering of the original coarse particles of emulsion or suspension into an undefined emulsion or homogenate.

Description

Homogenization principle.

(1) Shear effect

When the liquid under high pressure through a very narrow gap, the flow rate is as high as 150-300m / s. Large diameter particles in the gap is first stretched, and due to the turbulence of the liquid flow through the gap, or the rotor and stator for relative high-speed rotation of the material shear effect, is the liquid particles from the particles or oil droplets are sheared into finer particles.

(2) collision effect

When the liquid flow under high pressure through the homogenizer, due to the high velocity, the liquid in the large particles hit the metal surface at high speed or the impact of the liquid flow with each other, so that the large particles crushed into smaller particles.

(3) Cavity

Liquid in the high-speed flow through the homogeneous valve gap, resulting in a huge pressure drop. When the pressure is reduced to the saturation vapor pressure of the liquid, the liquid begins to boil and quickly vaporize, producing a large number of bubbles. When the liquid leaves the homogeneous valve, the pressure will increase again, so that the bubbles suddenly burst, instantly producing a large number of cavities. The cavities will release a lot of energy and produce high-frequency vibration to break the particles.

The three effects are synergistic. Different types of homogenizers have their own focus on the working principle.

Factors affecting the homogenization effect.

1, homogenization pressure

The size of the pressure selected for homogenization process determines the size of the energy obtained by the material. Generally speaking, the energy required to crush, depending on the size and hardness of the material particles, material formulations, temperature, the size of the final crushing fineness and different. Pressure is too low, too high pressure is also not necessary. The smaller the particle size of the material crushed, the greater the energy required. Generally speaking, the homogenization pressure increases, the average particle size decreases, and the rate of egg particle size decreases. This shows that both the use of very high pressure, homogenizer crushing fineness of the function is not unlimited.

2、Material particle size

The size of the initial particle size of the material and the uniformity of the particle size, is one of the important factors affecting the quality of homogenization. The process requires that the initial particle size of the material should not only be as small as possible (generally should not be greater than 50 microns), and shall be roughly processed by low-energy homogenizing equipment (such as colloid mills), so that the particle size can be as uniform as possible. The original material particle size is not uniform, uniform when it is difficult to obtain high-quality products.

3、Material characteristics

The content of grease in the mixture, again, is one of the important factors in determining its quality. When the world in the mixture of de energy density is the same, the increase in grease content means that the unit to obtain the average energy reduction, directly affecting the quality of the mixture. Experiments have proved that in a certain range, the reduction of the proportion of grease, but also to increase the homogeneous effect of one of the ways, the maximum proportion of grease content of the mixture should be less than 50%. Some material formulations of improperly proportioned stabilizer or homogenization pressure is too high, homogenization more times the material is too fine, homogenization of particles due to intermolecular forces and re-polymerization, particle size becomes larger and stratification, affecting the homogenization effect and storage period.

4、Material temperature

Material temperature, also closely related to the homogenization effect and homogenization path. Homogenization pressure is certain, in a certain range to improve the material temperature, can effectively reduce the viscosity and hardness of the material, improve the homogenization effect.

5、The number of homogenization

In the former rough processing based on the usual homogenization can be achieved on the basis of the process requirements. But some coarse, hard particles or homogenizer rated pressure is low, need 2-3 times homogenization or even more, to achieve fine and uniformity. However, it should be noted that the material has temperature rise after each homogenization, and the temperature after each homogenization should not exceed the allowable range of the process.

6、The distribution of the first level homogenizing valve and the second level homogenizing valve pressure

One-stage valve (high-pressure valve) and two-stage valve (low-pressure valve) the size of the selected pressure also involves the homogenizer work.

One-stage valve and two-stage valve is used in series, the size of the second-stage valve pressure, related to the size of the instantaneous pressure drop of the material through the first-stage valve, which is directly related to the processing effect of the first-stage valve and spool edible life. The experiment proves that the second-stage valve process select pressure should be controlled within 20% of the total system pressure.

Principle of high pressure homogenizer

(1)The high-pressure homogenizer takes high-pressure reciprocating pump (to know the principle of reciprocating pump, please click here) as the power transmission and material conveying mechanism, and conveys the material to the working valve (primary homogenizing valve and secondary emulsifying valve) part. The material to be handled will produce strong shear, impact and cavitation under high pressure in the process of passing through the working valve, so that the liquid material or the solid particles with liquid carrier can be superfine.

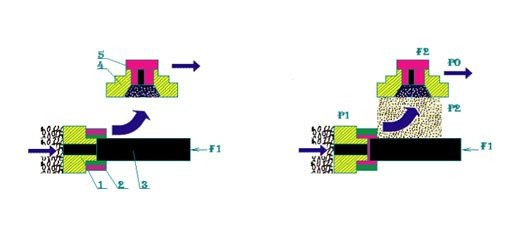

(2)Schematic diagram of working valve principle and introduction of particle refinement principle.

As shown in Figure 2, the spool and seat of the primary homogenization valve and secondary emulsification valve are tightly fitted together under the action of forces F1 and F2 before the material passes through the working valve. When the material passes through the working valve (Figure 3), the spool and seat are forced to open a slit by the material, and the pressure P1 and P2 are generated to balance the force F1 and F2 respectively. Effect of strong cavitation, accompanied by the material through the spool and the valve seat between the slit shear and impact with the impact ring impact generated by high-speed impact, so strong combined effect, so that the particles get superfine. Generally speaking, the pressure of P2 (i.e., emulsification pressure) is adjusted very low, and the role of the secondary emulsification valve is mainly to make the particles already finely distributed more uniformly. According to the information of Gaulin, the ideal result can be obtained in most cases by using the first stage homogenizing valve alone.

(3)Compared with centrifugal dispersion emulsification equipment (such as colloid mills, high-shear mixing emulsifiers, etc.), the characteristics of high-pressure homogenizer are:

- The refining effect is more intense. This is because the spool of the working valve and the valve seat are closely fitted to each other in the initial position, only to be forced out by the material liquid in the work of a slit; while the centrifugal emulsification equipment between the rotating stator to meet the high-speed rotation and not produce too much heat, there must be a larger gap (relative to the homogenizing valve); at the same time, because the drive mechanism of the homogenizer is a volumetric reciprocating pump, so theoretically speaking, the homogenizing pressure can increase infinitely, and the higher the pressure, the better the refinement effect.

- The refining effect of homogenizer is mainly using the interaction between the materials, so the heat of the materials is small, and thus the performance of the materials can be kept basically unchanged.

- The homogenizer can quantitatively transport the material, because it relies on reciprocating pump to feed the material.

- The homogenizer consumes more energy.

- The homogenizer has more wear and tear, and the maintenance workload is larger, especially in the case of very high pressure.

- The homogenizer is not suitable for the case of very high viscosity.