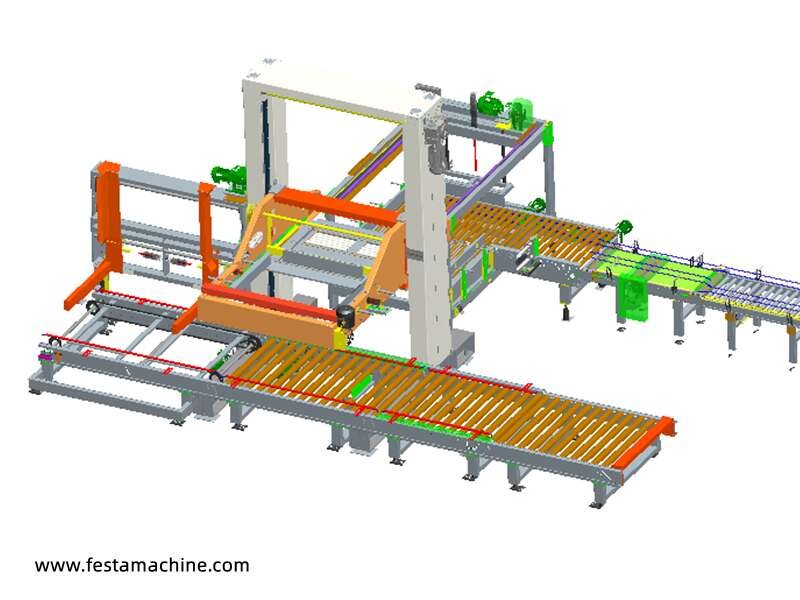

FDMD-40 Palletizer Machine

Production Capacity: 30-40 cases per minute

Operation Model: Fully-automatic

Maximum load per layer: 260kg

Maximum stacking height: 1750mm (including pallet height)

Benefit of FESTA FDMD-40 Case Palletizer Equipment

This palletizing machine can realize the functions of automatic feeding, automatic whole-lining, automatic lifting and lowering of arranged layers, automatic pallet supply and automatic palletizing. During production, Cases are conveyed by conveyor belt, and when they pass the steering device, the Cases are turned as necessary according to the counting program for automatic palletizing. When one layer of palletizing is completed, the layer pushing device pushes the arranged layer into the storage table, and then the arranged layer is lifted to a specific palletizing position with the storage table and the arranged layer is released, thus realizing one layer of palletizing. After one layer of palletizing, the storage table returns to the original state and the second layer of palletizing is repeated. When the palletizing is completed, the whole stack is automatically output.

Description

Case Input Device

Case conveying device

Through roller conveyors and belt separators, Cases are conveyed forward at certain intervals to prepare for steering.

Case steering device

Automatic steering of Cases according to the set arrangement.

Case grouping device

Through the power roller conveyor, the boxes are automatically grouped according to the palletizing form.

Case sorting device

Supply conveyor belt pushes the first row of sorted Cases into the storage layer device by cylinder and then pushes the second and third rows in order to form the sorting layer.

Automatic palletizing device

When the Cases form a layer according to a certain sorting, they are pushed into the lift by the pusher plate, and the lift rises the pallet to move forward to the upper part of the palletizing device and put it on the pallet (or the previous layer) smoothly to form automatic palletizing. The palletizing device relies on the frequency conversion motor to drive the chain to complete its lifting, lowering and forwarding (backward).

Automatic pallet supplying part

①Pallet supply device

The pallet magazine can stack 10 empty pallets and supply pallets to the palletizing device at regular intervals as required by the program. Powered by a separate motor.

②Pallet output device

When a pallet has reached the number of palletizing layers a signal is sent to automatically output the live pallets to the palletizing position. The solid pallets are conveyed to the designated position by roller conveyor belt (or connected with automatic winder).

Safety door device with multiple safety protection functions

Standby for missing boxes on the incoming conveyor belt.

Safety detection of horizontal movement limit of palletizing

Safety detection of vertical movement limit of palletizing

Automatic stop when the operator enters the safety isolation line

Material

Frame: SS41 (A3 steel painted)

Shaft: S45C bearing steel

Rollers: Stainless steel rollers

Machine cover: SS41 (A3 steel painted)

Guide plate: 304 stainless steel

Structural advantages of this machine.

- Safety guards made of aluminum alloy, engineering plastic and carbon steel spray plating conform to national standards.

- Adopt side inlet box: small footprint, simplify the conveying system in front of the palletizer, reduce the investment cost of the whole line equipment.

- Low-level palletizing type, international advanced design concept, more advanced and reasonable structure, lighter and smoother movement, and less power consumption.

- Siemens (SIEMNES) touch screen operation, to achieve man-machine dialogue, can display the production speed, the cause of failure and location, high degree of automation.

- Adopt Siemens PLC and Danfoss inverter to realize stepless speed control, programmable sorting and stacking of cartons, with fast communication ability and powerful diagnostic function to ensure the reliability of the system. Easy to operate, compact and reasonable structure, high degree of automation.

- Adopting AIRTAC cylinder, with reliable quality and performance, it can meet the high intensity and long working hours.

- Palletizing mode can be carried out on human-machine interface, easy to adjust. No need to change parts to complete a variety of palletizing methods.

- The safety door is equipped with electrical induction device, when the safety door is opened, the machine stops working, which can protect the personnel.

- 95% of electrical components are European famous brands, with stable and efficient performance, which can greatly save manpower.

- Carton supply system adopts brake motor control to ensure the cartons are transported according to the pre-set position

- Low noise, the noise is below 75db, in line with international standards.

- Comply with food hygiene requirements: adopt oil-free lubrication of pneumatic components, 60% of the moving parts are between the humanized design of lifetime without oil lubrication, which reduces a lot of usage cost for users.

Data Sheet

Machine Model | FDMD-40 Automatic Palletizer Machine |

Palletizing capacity: | 40 cases/min |

Operation mode: | human-machine interface |

Max. load per layer: | 260KG |

Maximum load per pallet: | 1600KG |

Maximum stacking height | 1750MM (including pallet height) |

Maximum pallet size: | 1300*1100MM (can be customized) |

Motor power: | three-phase five-wire, AC 380V/50HZ, 10KW Control voltage: DC 24V |

Air consumption: | 110NL/MIN (air usage: 6-8KG/ CM2) Air pipe connection size Φ10 |

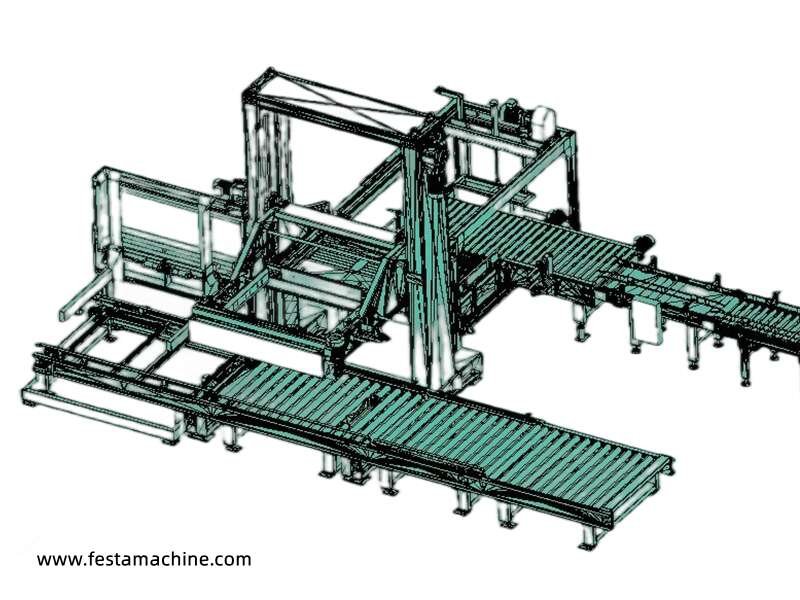

Equipment size: | (L) 8000MM × (W) 5200MM × (H) 3200MM |

Environmental conditions: | Temperature 0-40℃ Humidity 40-95% |

Equipment weight: | 7500KG |