Double Side Sticker Labeling Machine YX-200

Production Capacity: 2000-6000 bottles per hour

Operation Model: Fully-automatic sticker labeling machine

Label Material: paper label

Suitable Bottle: Glass bottle, PET bottle, flat bottle

Benefit of FESTA YX-200 self-adhesive labeling machine

The machine mechanism is divided into: conveying mechanism, bottle separation mechanism, correction mechanism, bottle pressing mechanism, scraping mechanism, marking mechanism, bottle guide mechanism and other parts. a number of advanced mechanical concepts are adopted, and the design of the mainframe part absorbs the labeling transmission mode of the imported machine. the problem of labeling instability is solved.

And through the programming control of German Siemens, French Schneider and other brands of electrical appliances, using the advanced man-machine interface system, the accuracy is controlled within ±1mm in the process of sending the label, and the frequency converter tests the bottle transmission synchronously, at the same time, the action of each important part adopts mechanical synchronous transmission, which ensures that the labeling is accurate, stable, reliable and efficient.

The whole machine is made of 304stainless steel and aluminum alloy, and the parts are standardized and interchangeable, which fully meets the requirements of GMP.

The machine is widely used in self-adhesive labeling in pharmaceutical, chemical, food, daily chemical and other industries, round, conical bottle, square, flat, oval bottle or round bottle positioning double-sided labeling.

Description

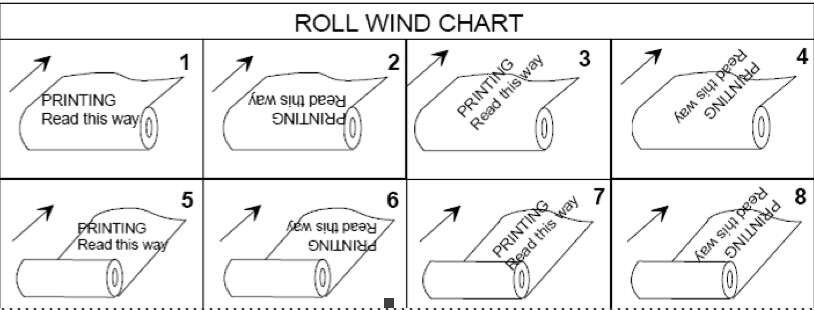

Double-sided sticky labeling machine: select the third and fourth graphics above.

Maximum label supply: diameter 350mm, paper roll inner diameter 76mm.

Label spacing: 2-3mm ±0.2mm.

The distance between the upper and lower edges of the label and the bottom of the backing paper: 2mm.

Base paper: need to choose 62 grams of white Glaxingdi paper, the paper is dense and has good internal strength and transmittance, firm and not easy to tear.

The die-cutting performance is excellent.

Basic gram weight: 62g/ “±5%”

Thickness: 55 μ m ±5%.

Tensile force: Machine direction: 16kg/25mm.

Horizontal: 7kg/25mm.

Tear resistance: machine direction: 25g / sheet.

Horizontal: 31g / sheet.

Transparency: 52%

Data Sheet

Labeling accuracy. | ±0.5mm |

Inner diameter of label drum core. | 76mm |

Maximum outer diameter of label roll. | 380mm |

Label width. | 10-110mm |

Label length. | 20-360mm |

throughput. | 2000-6000BPH |

Power source. | 220V,50HZ |

Installed power. | 3500w |

Machine weight. | 450KG |

Machine parameter | 3000*1400*1600mm |