DCGF32-32-8 Carbonated Beverage Filling Machine

Production Capacity: 8000-10000BPH(500ml)

Main Material: Food grade stainless steel 304

Filling Temperature: 4℃ cold drink filling

Suitable Bottle: 300ml, 500ml, 1000ml, 1500ml

Benefit of FESTA DCGF32-32-8 Carbonated Filling Machine

Combined with many years’ experience of beverage bottling plant, we have improved the pipeline system of the filling machine and optimized the structure of the filling valve. At present, the stability of our carbonated soft drink filling machine has been greatly improved, and the phenomenon of a large amount of foam in cold drink after filling has been greatly reduced.

DCGF32-32-8 PET bottle 3 in 1 soft drink filling machine is a kind of liquid filler with medium speed and stable operation, which is developed by FESTA by introducing advanced technology from Europe. It is mainly used for filling and packaging of aerated beverages, cold drinks, Pepsi, Coca Cola and other drinks. It has the advantages of low noise, high intelligence and convenient maintenance, so it is a perfect filling equipment for beverage production enterprises.

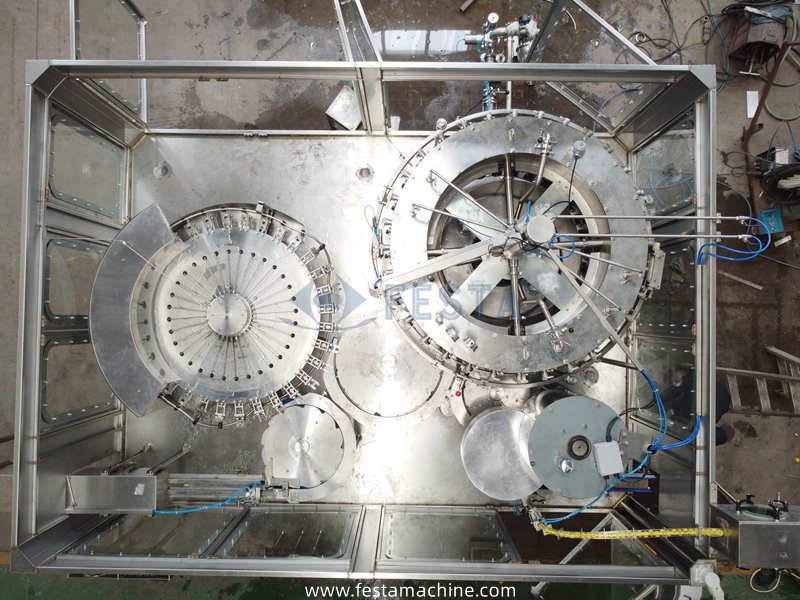

The machine has three main functions, that is to say, there are three main parts.

Bottle washing machine.

Empty bottles are transferred to the inside of the machine through air conveyor to enter the continuous bottle washing program.

Filling machine.

The washed empty bottle is transferred to the isobaric filling machine through the star wheel, and the filling machine can smoothly fill the empty bottle with low temperature carbonated beverage/drink.

Capping machine.

Under the work of the capping machine, the sorted cap rotates quickly and intact at the mouth of the bottle to ensure that the liquid inside the bottle will not spill.

These three processes are completed successively inside the machine.

After coming out of the machine, a bottle of cold drink in PET bottle is ready.

If you still don’t know the whole process, click video tab to watch the working video of DCGF32-32-8.

Machine Model | DCGF32-32-8 |

Production Capacity | 8,000-10,000 bottles per hour |

Suitable Container | PET bottle Diameter: 55-100mm Height: 186-310mm |

Washing Nozzle | 32 |

Filling Nozzle | 32 |

Capping Nozzle | 8 |

Voltage | 380v 50Hz |

Main Motor Power | 4kw |

Air Consumption | 0.7Mpa 0.8m³ per minute |

Washing Water Consumption | Washing water pressure: 0.25MPa Washing water consumption :1500kg/H |

Filling Water Consumption | 6000-8000kg per hour |

Dimensions | 4060X3000X2700 |

Weight | 8000kg |