After years of unremitting efforts, PET aseptic cold filling technology has become more and more perfect, producing more and more varieties of beverages, including fruit and vegetable juice drinks, tea drinks, sports drinks, carbonated drinks, water and so on. At present, PET bottled dairy beverages are very common in North America and Europe. The application of PET bottles in the beer field has also become more realistic by adding a proper barrier layer during the blowing process to solve the problem of bottle permeability.

Table of Contents

ToggleKey points of PET aseptic cold filling technology

The product is sterile after UHT sterilization

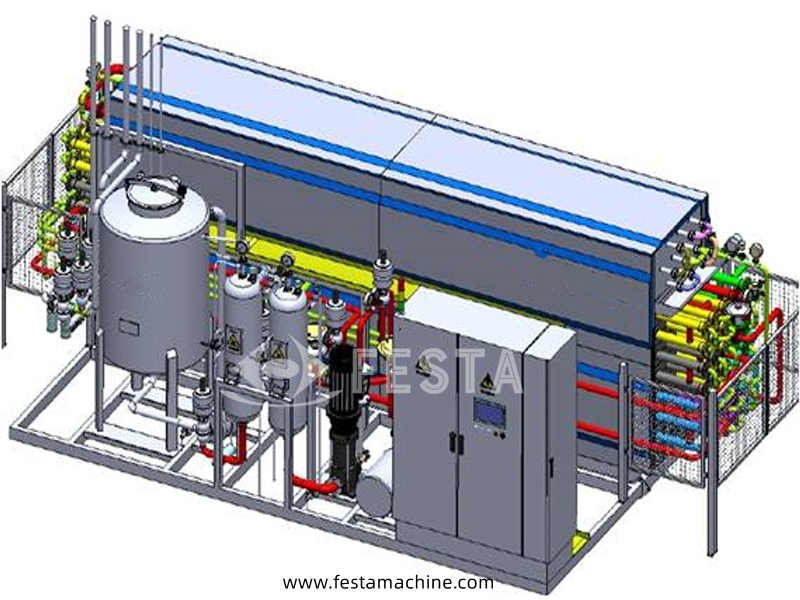

PET aseptic cold filling production line generally uses UHT sterilization process to achieve this purpose. There is no clear definition of UHT sterilization internationally, and it is generally considered that the sterilization method with temperature at 138-145℃ and time between 1-30 seconds is high temperature short time sterilization, which is the process usually used for most aseptic packaged foods. PET aseptic filling production line in the design of UHT sterilization process, to choose the appropriate When designing the UHT sterilization process, it is important to select the appropriate sterilization temperature and time to maximize the sterilization value (Fo value) of the product, while also ensuring that the flavor and nutrients of the product can be retained to the maximum extent. At present, PET aseptic cold filling production lines mostly use tubular UHT sterilizers.

Sterilization of packaging materials is the most critical step in the production process of aseptic cold filling

Since standard PET bottles are not heat resistant, only chemical reagents can be used for sterilization. To ensure that the bottles and caps are effectively sterilized and that the chemical reagents do not affect the product, aseptic filling takes the following measures.

- 1. Require the original colony count of the initially blown bottle not more than 10CFU / bottle

- 2. The bottles are transported with sterile air and equipped with air conveyor belt

- 3. Sterilization of the bottle interior with peracetic acid disinfectant, which can achieve a high sterilization effect

- 4. Sterilizing agent is used for the outside of the bottle at the same time

- 5. The disinfectant has automatic recovery and concentration measurement system to ensure stable concentration of disinfectant

- 6. The residual disinfectant in the bottle is rinsed with sterile water and then blown dry with sterile air to ensure that the residual disinfectant will not affect the material

- 7. Bottle caps are generally sterilized by soaking in disinfectant, and the sterilization effect is guaranteed by controlling the soaking time

Filling equipment to aseptic condition

The main equipment of aseptic cold filling requires a hygienic food-grade design and has advantages mainly in several aspects such as piping and valve technology, polishing of material surfaces, surface design of important areas, selection of corrosion-resistant materials, etc. It also comes with a CIP system, a SIP system and an external foam cleaning system (COP) for the equipment. In addition, aseptic cold filling machines are designed with their own unique aseptic filling valves, and these measures ensure that the equipment side does not bring secondary contamination to the material. Since the PET bottle will not shrink after cold filling, so that there will be some air between the material and the cap, the oxygen in it will slowly oxidize the material during the storage process, thus causing the beverage to deteriorate. Therefore, aseptic cold filling equipment will add a set of nitrogen (or other inert gas) replacement system to blow the top air away to ensure that the product is not oxidized as much as possible.

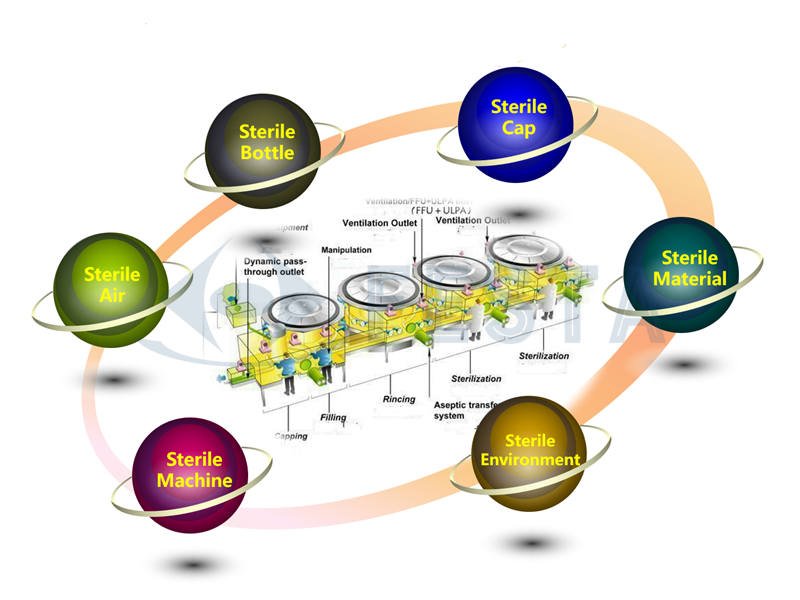

Filling and capping in a sterile environment

PET aseptic cold filling line aseptic environment is maintained, the general use of air purification room isolation measures. At present, food processing enterprises use purification room is developed from the pharmaceutical industry, the technical level has a unified standard.

PET aseptic cold filling main filling machine area requires the design of D100 level aseptic space, outside there are 10,000 level purification room, through the purification room of the aseptic wind filtration system to ensure the cleanliness of the air within the filling environment, so that the material will not be suspended in the air microorganisms secondary contamination, while controlling the temperature and humidity of the purification room to ensure that the aseptic filling machine is always in good working condition.

In the whole environmental system, the operator is the biggest source of pollution, design air purification room in the purification of air at the same time, but also very good to reduce the pollution brought by personnel; operators in the entry of 10,000 class purification room, to go through the air shower sterilization; 100 class purification room design small and practical, can make the operator does not destroy its sterile environment for operation; purification equipment can be automatically cleaned and disinfected on the inner surface.

Establishment, monitoring, recording and control of critical control points for aseptic cold filling lines

The production of PET aseptic cold filling line is a very complex continuous production process, in which any operational error or secondary contamination of product microorganisms may cause the failure of the entire aseptic control system and affect the safety of the entire batch of products. So the establishment of a scientific and perfect monitoring and control system is the key factor for the successful operation of aseptic cold filling production line, and the HACCP management system is commonly used in the beverage industry.

HACCP is the abbreviation of Hazard analysis and critical points, which is a management method with high logic and evaluation system that enables food manufacturers to identify and control potential hazards in a timely manner in the production environment, so as to prevent unqualified products. The system includes seven basic principles, including the identification of critical control points (CCP) to control hazards, the establishment of critical limit values (CL) for each control point, and the establishment of procedures to monitor each control point are the key parts of the system. Only by managing and controlling according to the HACCP system can we truly ensure product safety.

Hot filling process

Hot filling process can generally be divided into two types: one is high-temperature hot filling, that is, the material after UHT instant sterilization, cooled to 85-92 ℃ for filling, the product needs to be refluxed during filling to maintain a constant filling temperature, and then maintain that temperature for bottle cap sterilization; one is the material sterilization after filling at 65-75 ℃ for pasteurization and adding preservatives. These two methods do not require separate sterilization of the product, bottle and cap, but simply keep the product at a high temperature for a long enough time to achieve the sterilization effect.

Comparison of two filling process technologies

The biggest difference between the two filling processes compared to each other is the different heating time of the beverage. We all know that the longer the heat treatment time, the greater the impact on the quality of the beverage. Aseptic cold filling only uses UHT ultra-high temperature sterilization, the material is heated for a short time, less loss of nutrients, and no significant changes in quality and taste, and the sterilization effect can be fully guaranteed at high temperatures; while the sterilization method used in hot filling puts the material in a high temperature state for a long time, affecting the taste, color and heat-sensitive nutrient content of the product. Hot filling process determines the hot filling method is only suitable for the production of highly acidic products, because the high acid environment itself has an inhibitory effect on microorganisms, for low-acid beverages is not good to ensure the safety of its products, the product defect rate is higher. If the hot filling process is used to produce neutral tea beverages, preservatives need to be added. For aseptic cold filling, since the whole process is carried out under aseptic conditions, the process is highly adaptable and can produce a wide range of product types, including neutral tea beverages, dairy beverages and various other beverages, with only appropriate adjustments to the pre-treatment equipment to change the product type.

| Name | Hot filling | Aseptic cold filling |

| Bottle and cap quality requirements | Crystalline heat-resistant PET bottles (able to withstand temperatures of 85°C-92°C without deformation) and special heat-resistant caps are required | Can use ordinary PET bottles (maximum heat resistance 60℃) and standard caps |

| Material requirements | Keeps at high temperature for a long time and adds preservatives | UHT sterilization of the material and cooling to room temperature |

| Bottle sterilization requirements | and not sterilized or simply rinsed with ozonated water, chlorinated water | Must be sterilized by soaking or spraying with sterilizing solution |

| Bottle cap sterilization requirements | Can be UV irradiated or simply rinsed with chlorinated water | Must be sterilized by soaking or spraying with sterilizing liquid |

| Filling environment requirements | Requirements are not as high as aseptic cold irrigation, 100,000 class purification can be | Class 100 purification in filling area; Class 10,000 purification in filling room and pre-filling line, and almost no microorganisms exist |

| Filling equipment requirements | Filling system using external circulation and requires a CIP | Non-contact filling method, which requires perfect CIP and SIP system and strict requirements on filling space requirements and outside packaging delivery method |

| Filling post requirements | Need reverse bottle sterilization chain and spray cooling equipment | No post-processing required |

| Practicality | Process environment is simple to operate, quality control management is relatively relaxed | The process environment is extremely complex, and the quality control management requirements are extremely strict |

| Operational risk | Smaller | Large |

| Impact on product flavor | Has a certain impact | Minimal impact |

Comparison of two types of PET bottles

As can be seen from the filling process, the two filling methods have different requirements for PET bottles. The hot filling process requires PET bottles to withstand high temperatures of 85-92°C without deformation, which requires an increase in the crystallinity of the PET material, as well as limiting the generation of induced stresses when blowing the bottles. The PET bottles used have the following characteristics: thick walls and a high degree of crystallization to enhance thermal stability; clear bottle reinforcement to prevent thermal shrinkage; and the requirement for a crystalline bottle mouth, which greatly limits the freedom of bottle design.

Aseptic cold filling can use standard PET bottles (maximum heat resistance of 60°C) and standard caps, which significantly reduces the cost of bottles and caps, and also allows the freedom to design unique bottle shapes according to product characteristics for personalized packaging.

Outstanding advantages of PET aseptic cold filling compared to hot filling

High quality product

The high quality of aseptic cold-filled products is ensured by the shortening of product heating time, the manufacturing and maintenance of aseptic environments, and scientific management practices.

Low cost

The savings in raw materials, energy consumption and personnel make it possible for the low-cost advantages of aseptic cold filling products to become apparent in a short period of time.

Wide applicability

The improvement of aseptic filling technology has made various beverage filling processes closer and closer in applicability.

| Item | Hot-filled PET bottles | Aseptic cold-fill PET bottles |

| Bottle Weight | Heavy | Light |

| Bottle neck | Special crystalline bottle neck | Standard bottle neck |

| Raw material ratio | High requirements | Standard |

| Bottle design | Special bottles with hot ribbed plates | Customizable bottle design |

| Temperature resistance | 85-92°C | 60°C |

| Oxygen permeability | Bottle wall thickness, low oxygen permeability | Thin wall, high oxygen permeability |

| Caps | High temperature resistant bottle cap | Standard cap |

| Bottle and cap cost | High | Low |

If you are looking for an aseptic filling machine system, you can leave your inquiry here and our engineers will contact you within 8 hours.