4 Cavity Blow Molding Machine FST-4000

Production Capacity: 3500-4000BPH(500ml)

Control mode: Fully-auto PLC control

Machine material: Carbon steel

Container: PET bottle 0.5liter-1.5liter

Benefit of FESTA FST-4000 Bottle Blow Molding Machine

FST-4000 is our most stable two stage automatic bottle blowing equipment, using 4-cavity bottle blowing mold, the maximum blowing 1.5Liter bottle, suitable for blowing PET raw materials of any shape of carbonated beverage bottles, mineral water bottles, cosmetic bottles, large diameter bottles, high temperature bottles and other packaging containers.

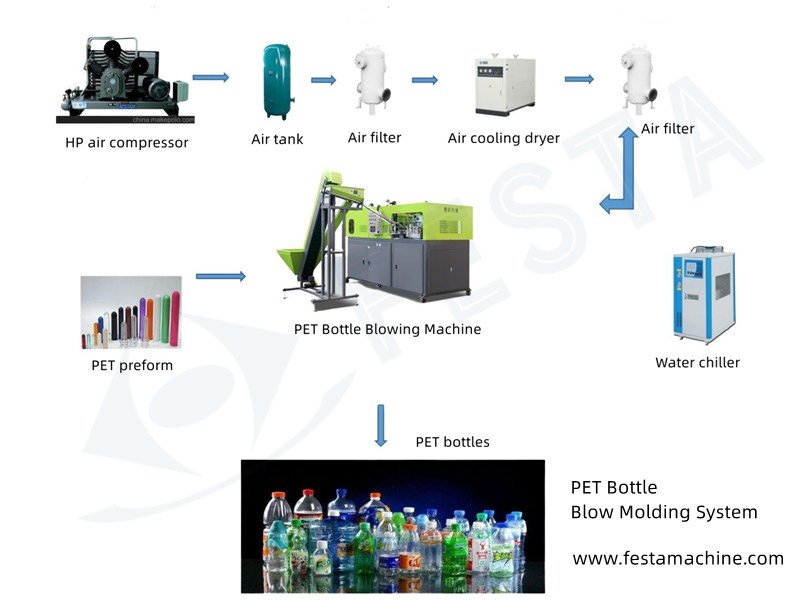

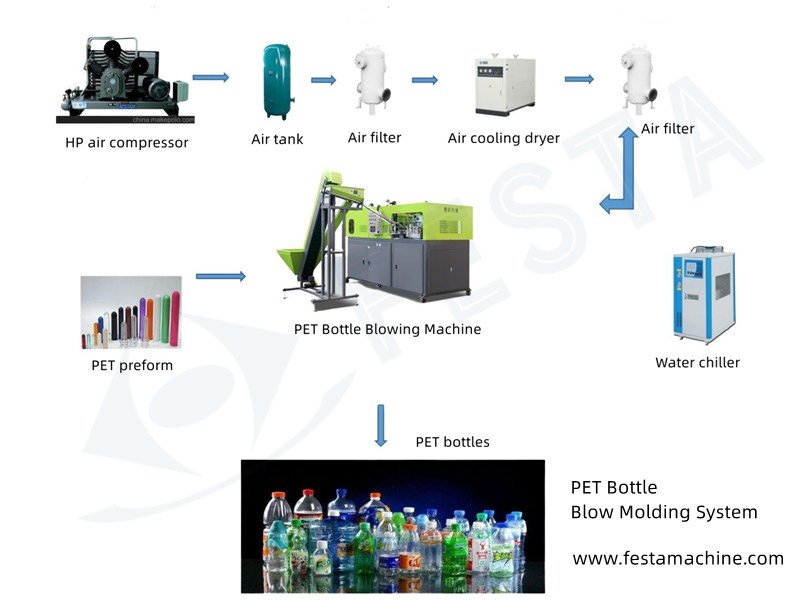

The process of bottle blow molding

- The preform is transported to the sorter machine by preform feeding machine.

- The bottle preform is put into the preform holding nozzle by a manipulator.

- The preform is transported to the heating system through the chain, and the preform is heated evenly in the heating light box.

- Seal, stretch and blow the bottle in the blow molding machine.

- The finished bottle is picked up automatically by the manipulator.

- Complete the bottle blowing process.

Machine Model | FST-4000 | |

Productivity | Depend on bottle design | 3500-4000BPH(500ml) |

Bottle type | Body diameter | 30mm-90mm |

Height | 80mm-330mm | |

Neck diameter | 20mm-38mm | |

Bottle mould | Cavity | 4 cavities |

Mold thick | 300mm | |

Mold | 260*300*370mm | |

Main machine power | Electrical source power | 380v 50Hz 3Phase |

Rated Power | 50kw | |

Really working power | 15kw | |

Air source | LP air compressor | 1.0m3/min 1.0MPa |

HP air compressor | 1.2m3/min 3.0MPa | |

Cooling water | Cooling water | 20L/min |

Size | L*W*H | 3400*1500*2300mm |

Weight | 3500kg | |