High speed carbonated soft drink CO2 mixer system(QHS series)

The High Speed Carbonated Drink Mixing Machine is the most advanced mixer which is used to all kinds of carbonated beverage (such as coke, Lemonade product) according to requirement scale mix water , syrup, carbon dioxide well. It is necessary and key equipment for soft drink product especially for medium to high requirement .

Details About High speed carbonated soft drink CO2 mixer system(QHS series)

QHS series drink mixer is designed and made for improving the proportion of water, syrup and carbon dioxide. It adopts foreign advanced technology—static mixer to lighten water layer, increase carbonizing time, assure mixing result and deoxying. It adopts high-quality water pump and

SEIMENS electrical equipment and other parts to form complete automatic control system. It has coordinating action, beautiful appearance, convenient washing, high automatic level and other

advantages. It is suitable for mixing all kinds of drink, such as soda water, fruit juice, cola and other soft and hard drink.

The High Speed Carbonated Drink Mixing Machine is the most advanced mixer which is used to all kinds of carbonated beverage(such as coke, Lemonade product) according to requirement scale mix water , syrup, carbon dioxide well. It is necessary and key equipment for soft drink product especially for medium to high requirement .

Characteristic

1.the machine is adopted the most advanced technology in chemical industry—- static mixer( namely carbonizer) , big area mixing and small resistance, high efficiency and low energy consumption, uses stable function and low noise multi-stage centrifugal pump to guarantee smooth machine operation .

2.the machine adopts high accuracy proportional action needle valve and pneumatic angle valve, not only keep mixing accuracy, also avoid cross flow.

3.the machine uses carbon dioxide flow back to replace oxygen, save carbon dioxide at same result.

4.The machine is convenient to change air content, according to requirement to operate and adjust .

5.Has prefect automatic control system, with advantages of simple structure, continue working, match well and totally automatic .

6.The machine has reasonable structure to use CIP system, so easy cleaned by chemical material , steam sterilization and clean by water , totally meet sanitary requirement .

Leave your questions, we will reply to you within 11hrs

Our Professional Workers

Machining Equipment

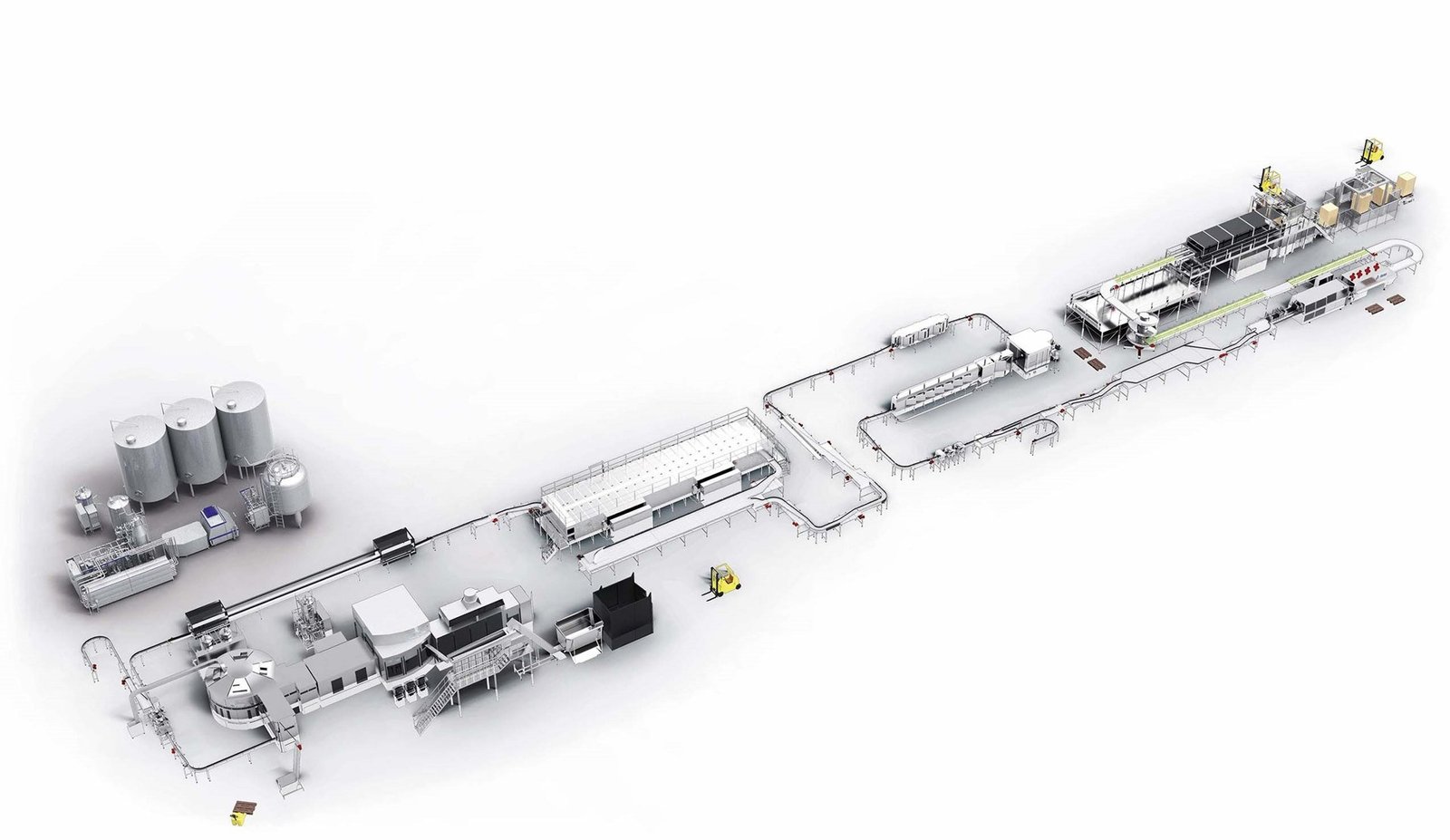

Successful Bottling Line Projects

We only work with Top supplier

Packaging and Delivery

Transfer your idea to final product

FAQ about Festa

We are an Original Equipment Manufacturer, so that we can provide you high quality machines in reasonable price. If you have plan to visit China, please visit our factory to check it.

Design and production time is around 45 to 60 days, the exactly time depend on what kind of machine you order. The shipping time is based on your destination port.

We will arrange our experienced engineers to your factory for installation and commissioning, and train your staff how to operate the whole production line.

According your project, we will send one or two engineers to your plant, it will take about 15 days to 35 days.

We can design the machines according your requirements (material, power, filling type, bottle type, automation level). We will also give you professional suggestions according to our experience.

We offer you high quality machines with 12 months warranty and supply life-long technical support.